The purpose of this wrench is to make it easier to assemble and remove the fuel pump from a VP-44 Cummins ISB 24-valve diesel engine. This would improve the efficiency and frustration of working on these engines.

This assignment covers the specific components of the wrench. Last Assignment I created modules of motion for the wrench. This consisted of exploring different hinge options, exploring their strengths and weaknesses

through a multidimensional comparisson of each module. In this assignment I will chose the best module for the wrench using a decision matrix to find the best option. Once I have discovered this module I will create

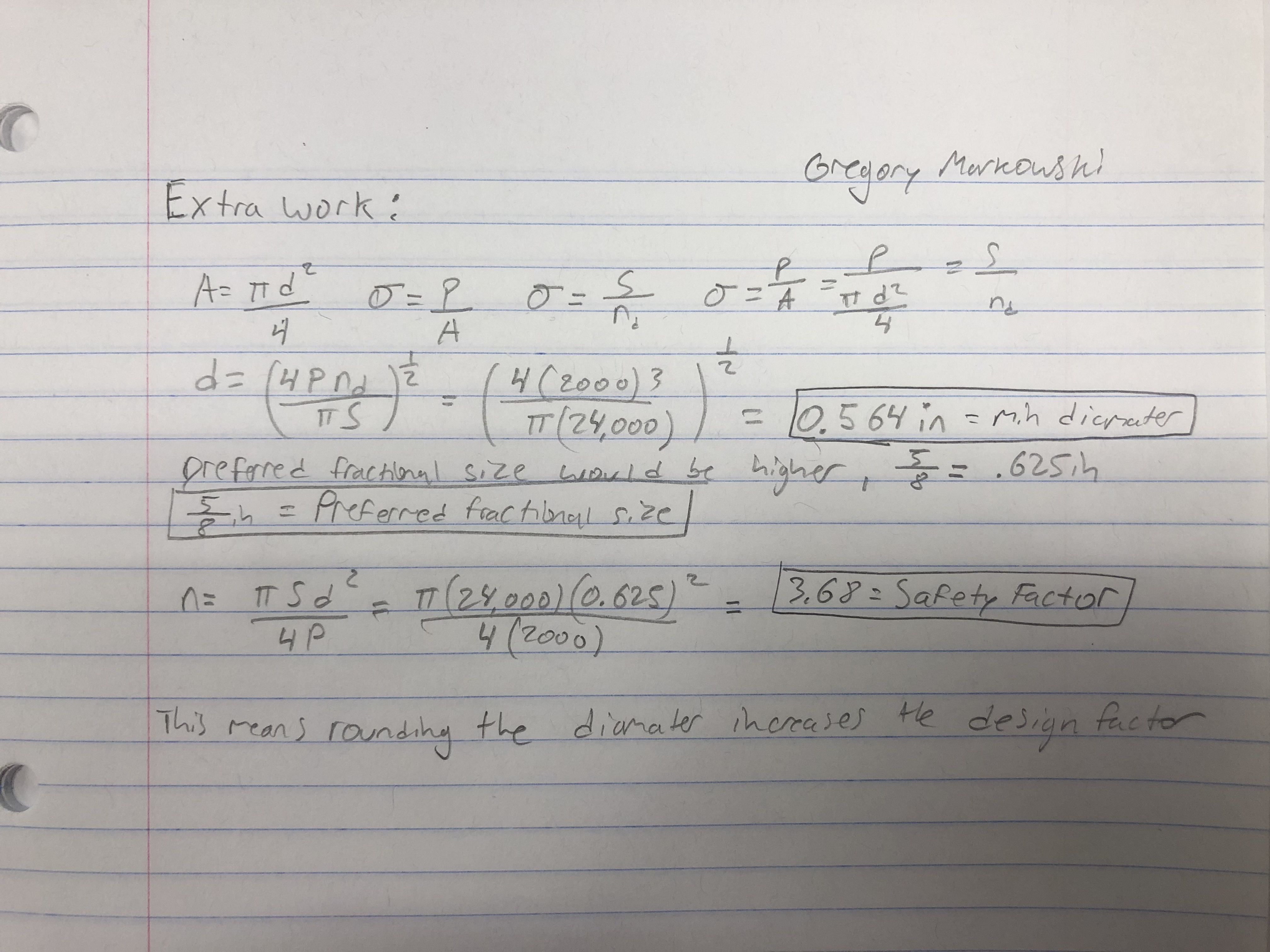

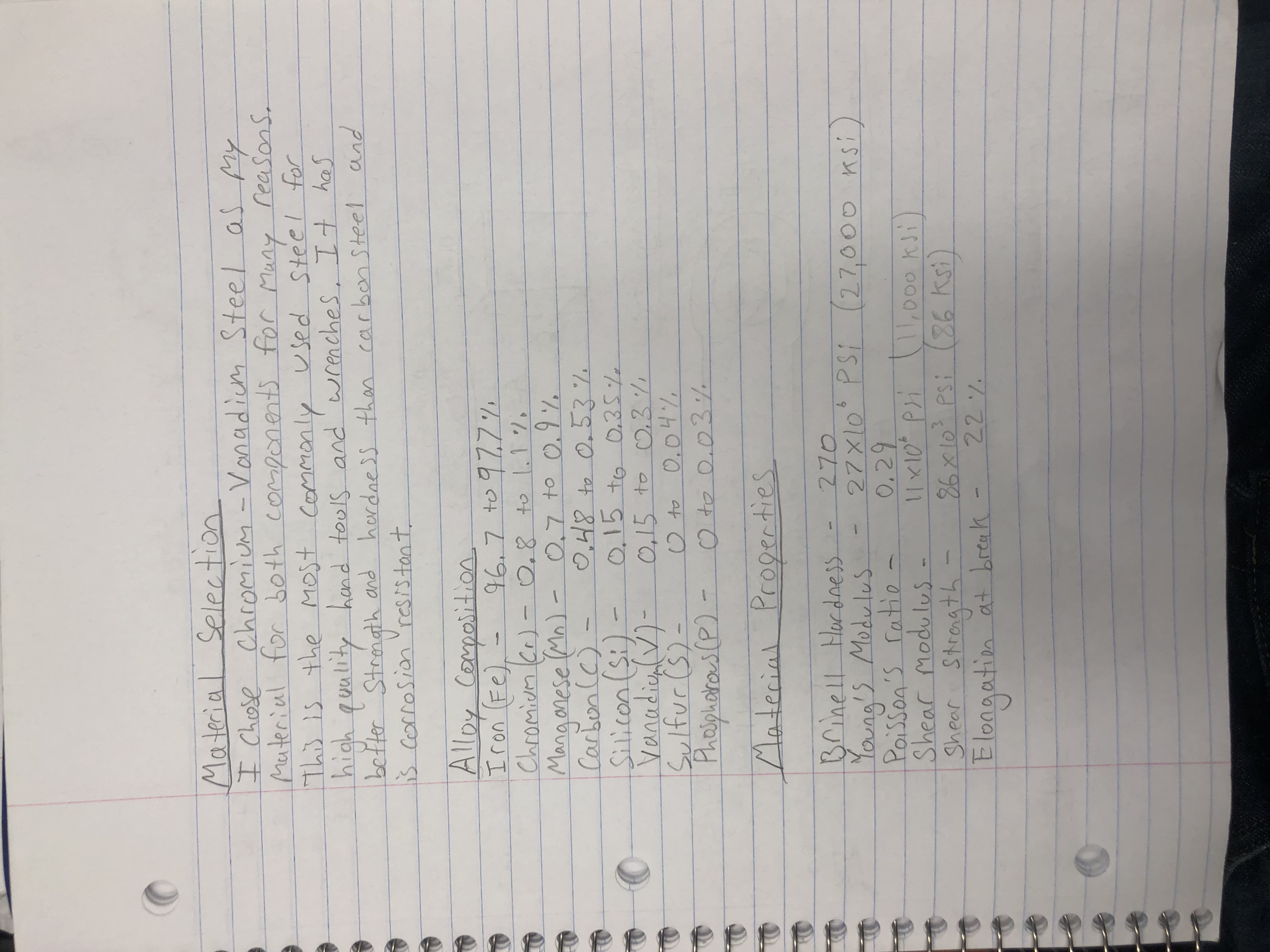

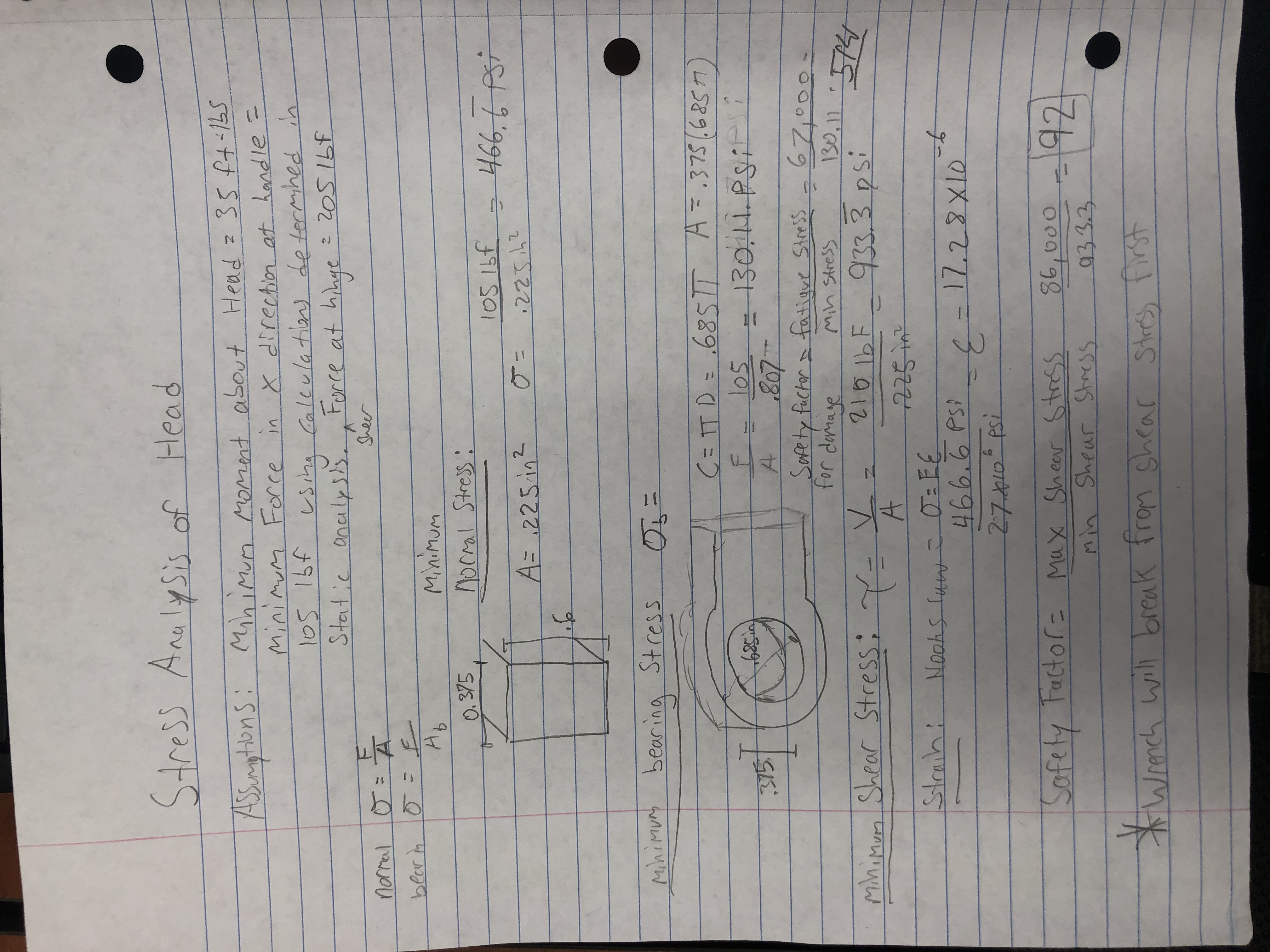

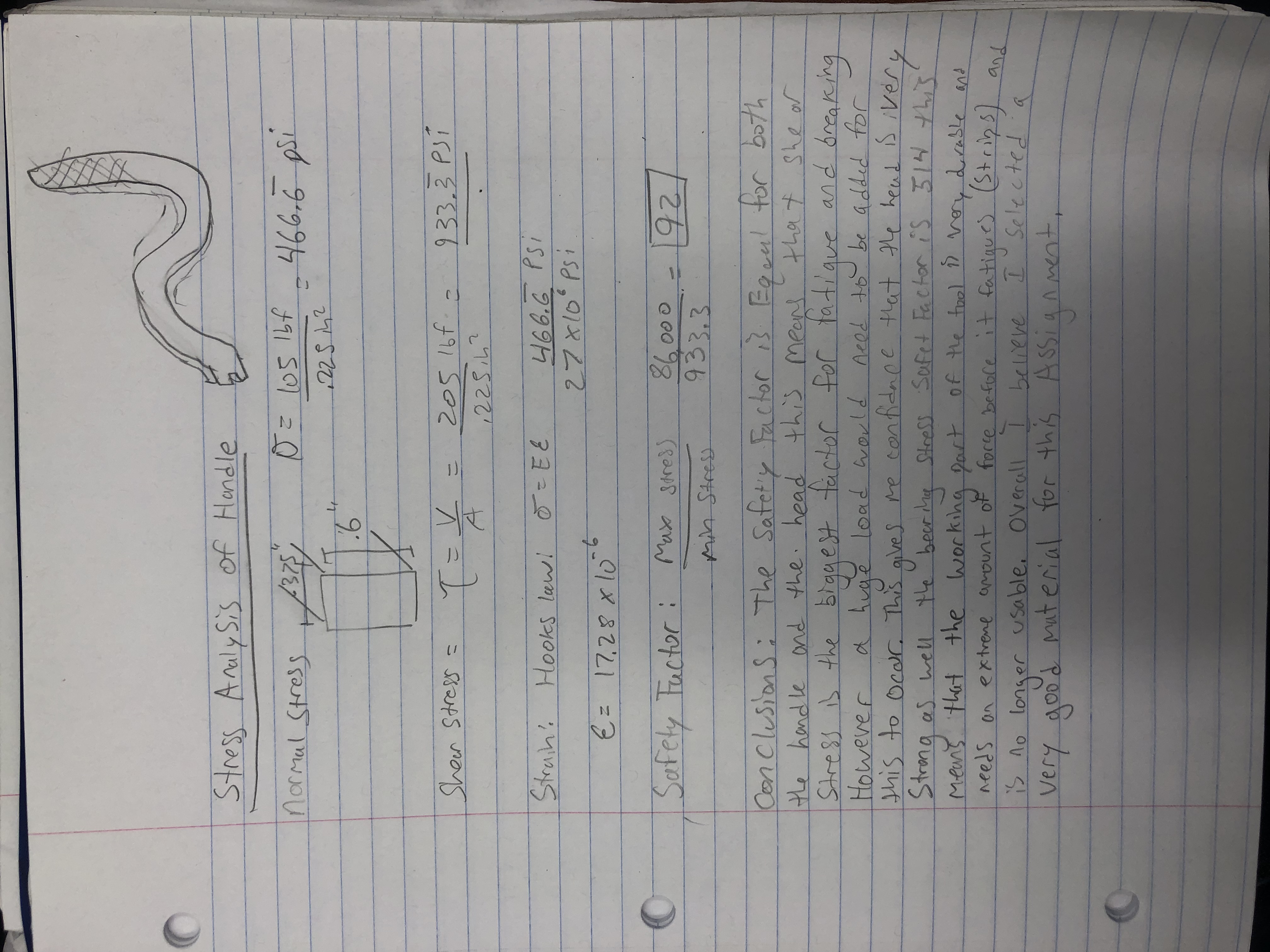

detailed models of the tool components including the selectred module. Using knowledge from my solid mechanics course I will calculate normal stress, Bearing stress, Shear stress, Hooke's Law, and safety factor choosing

a material that satisfies the dimensional, corrosion, and strength requirements.

The wrenches will be used at a constant rate of 1 rad/s, will accept 15mm bolts, are no longer than 10 inches, and are made of a Chromium Vanadium alloy drop forged and plated in chrome. The moment about the hinge

will be calculated to help determine necessary strength at this location. I will also calculate normal, bearing, and shear stresses aswell as strain and safety factor to determine the validity of my chosen steel.

I am assuming the material properties listed on the material sheet aswell as the forces calculated in the static analysis sheet.

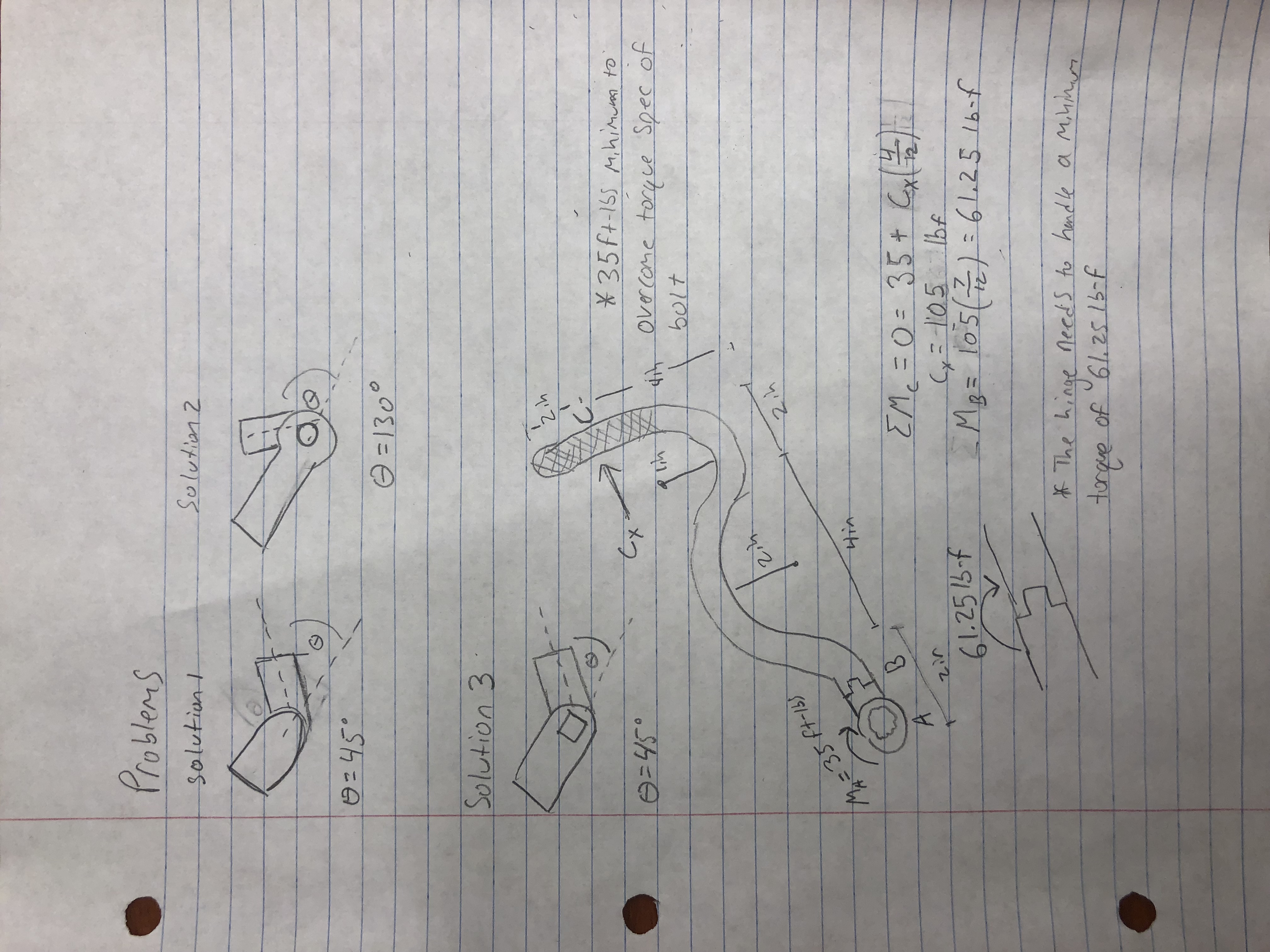

The best hinge/module design was design hinge one, it had the best cost, ease of use, and aesthetics. It had decent Funtionality, but lacks durability.

This hinge has the least number of parts reducing complexity, the tight tolerances make it stiff so the position dsired will be maintained,

and it looks the best because it is press-fit and is more streamlined with the rest of the wrench. This design lacks durability because it is

press fit and the internal mechanism that holds it together will wear out over time faster than a pin or bolt. The other hinges require more parts,

hinge 2 has a range of mobility that is unecessary for the application. Hinge 3 has many parts to increase the functionality and ease of use by allowing

the hinge to lock, however, this makes the part uneccesarily complex.

This is a Press fit hinge and is chosen as the best option for the wrench. It has tight tolerances which make provide a large amount of friction. In this

case this is good as the hinge will maintain its position better. A press fit hinge is useful as id does not require a pin as an axis and maintains most of

its strength.

Click Here for files: Selected Solution

This is a standard pinned hinge with both sides being opposite symmetrical held in place with a pin. The larger axis allows for a larger range of motion

which is not necessarily a good thing.

Click Here for files: Hinge 2

This is a locking hinge almost a cross between the first and second solutionslow tolerance like the first and pinned with a bolt like the second. This one differs

because it offers a bolt and nut mechanism that locks a specified angle in place.

Click Here for files: Hinge 3

This is the completed component assembly including the head of the wrench and the handle. The two components are made of

Chromium-Vanadium steel for their high end Strength and corrosion resistant properites. See Material sheet for more details.

Click Here for files: Component Assembly

This is a fairly standard 15mm wrench head its major diameter being 0.685in while its minor diameter is .589in

with its major difference being the hinged connection point as sign on the right side of the image below. Noting the calculation

page you can see that the bearing stress on the points of contact with the bolt head will cause no issue with use fatigue.

This proves the concept of design and material selection.

-note assignment 3 for chosing of box end style wrench-

Click Here for files: Wrench Head

This is a an oddly shaped handle but it serves a unique purpose for those that work at cummins. The handle is

rather simple but very effective, the material chosen can be easily manufactured to this shape under heat and pressure.

The safety factor for the handle is 92 meaning an immense load must be added before it breaks.

Click Here for files: Handle

I learned that that it is important to think about the bigger picture, I made the mistake of thinking too narrowly

which made making three concepts very detail oriented making this assignment unnecessarily difficult. If I were to

change something I would have been less specific with my concepts in the last assignment. I also learned how to use

creo more efficiently and creatively.

To Advisee Antonio Kraychete

Overall very good job, the presentation is clear, simple, and to the point. Maybe you could make your Description under yourTo Advisee Daniel Todd

The organization of your website is very good, simple and to the point. Maybe next time you could make your design images