Unit 3a Assignment

Introduction

On May 25, 1979 at the O’Hare Airport in Chicago, Illinois, the American Airlines Flight 191, a DC-10, experienced number 1 engine/strut failure from the left wing. This led to sudden engine and strut separation after takeoff which then caused loss of electrical and hydraulic power to flight controls. Shortly after liftoff Flight 191 was beginning to rotate then the left engine and strut assembly began to completely separate from the left wing as one and fell onto the runway. The American Airlines airplane began to turn and roll towards the left and the nose of the plane started to pitch down which led to the airplane to begin to descend towards the ground. Flight 191 crasehd 4680 feet away from the departure end of the runway.

The main cause of this engineering disaster was a combination of design flaw and human error.

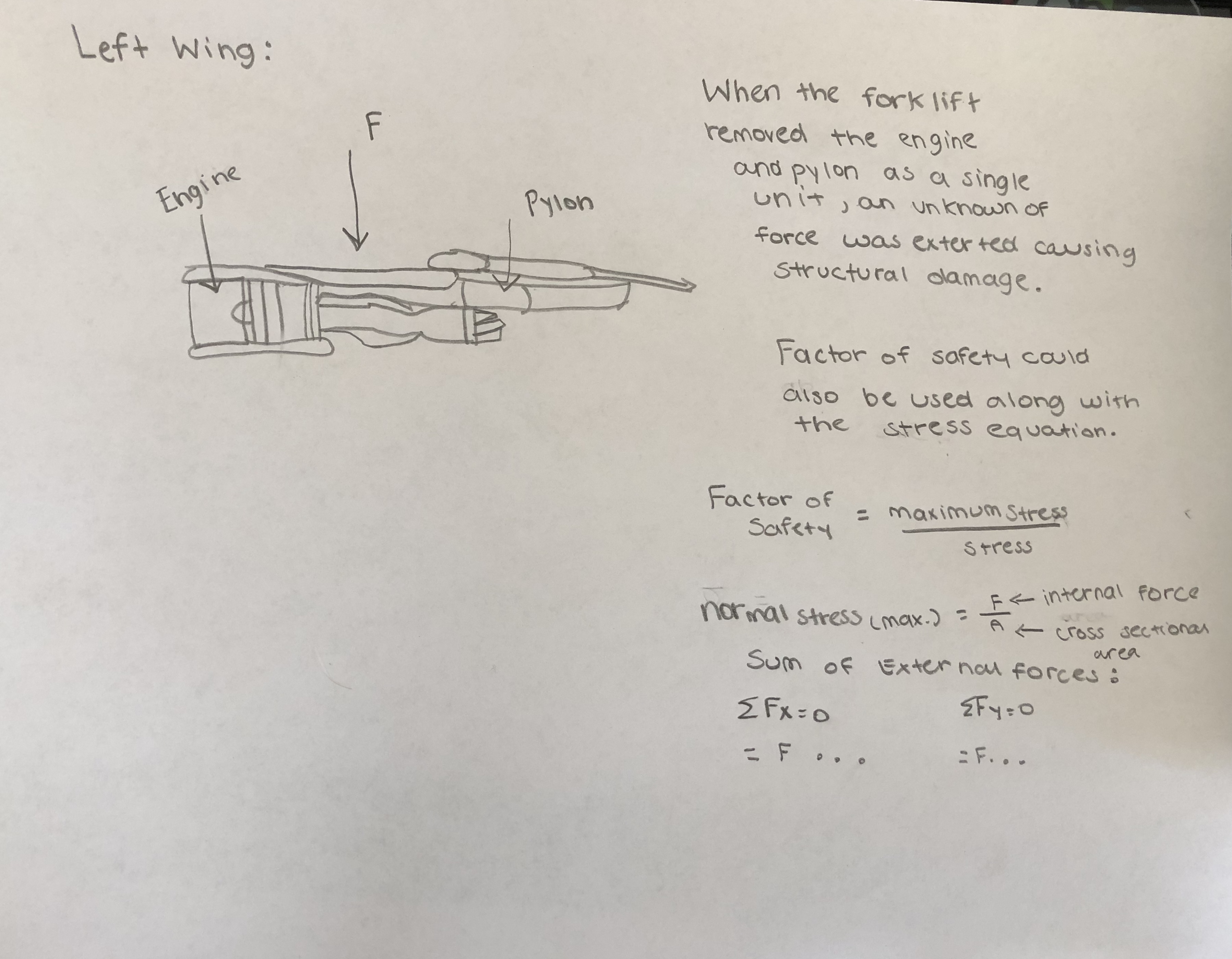

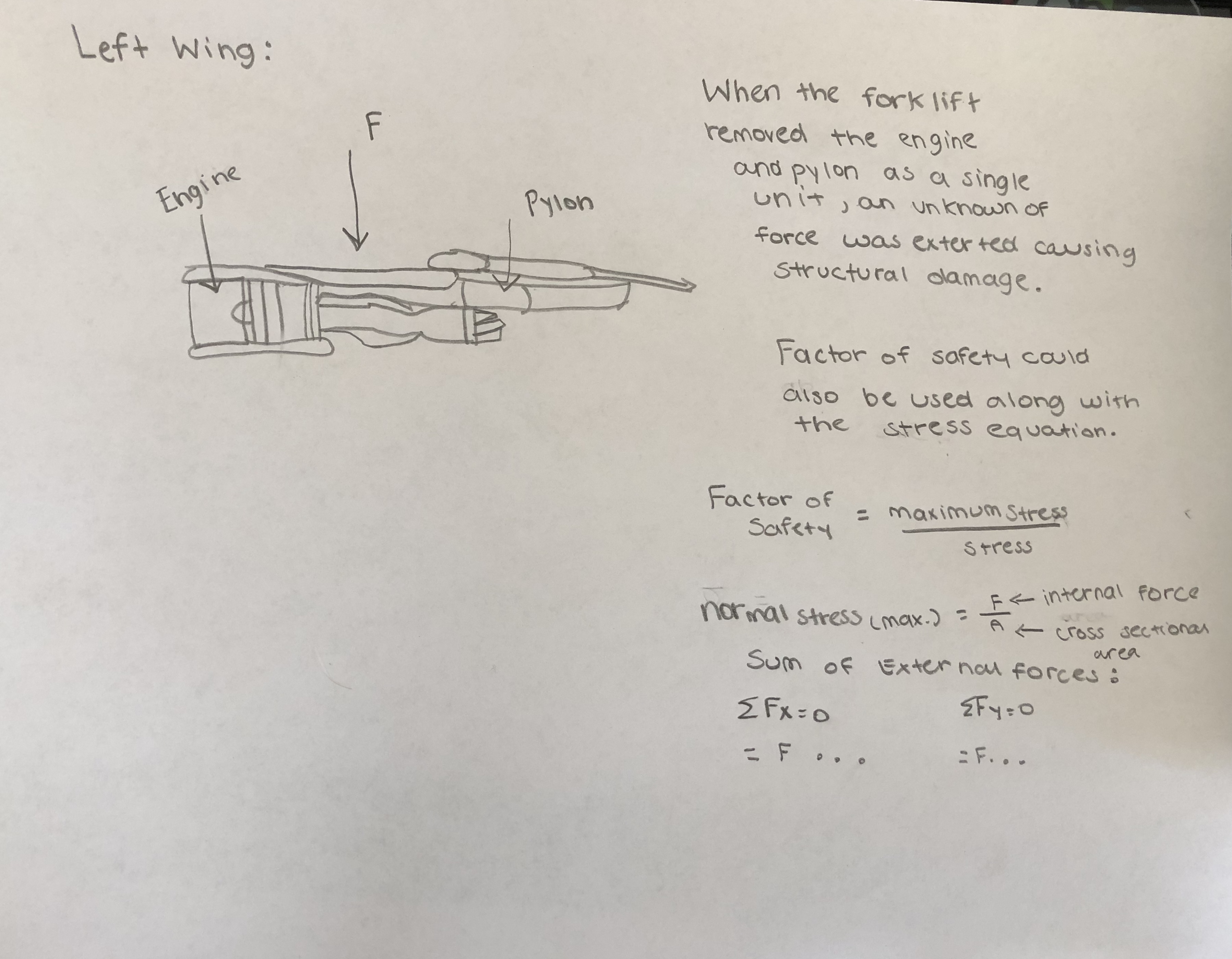

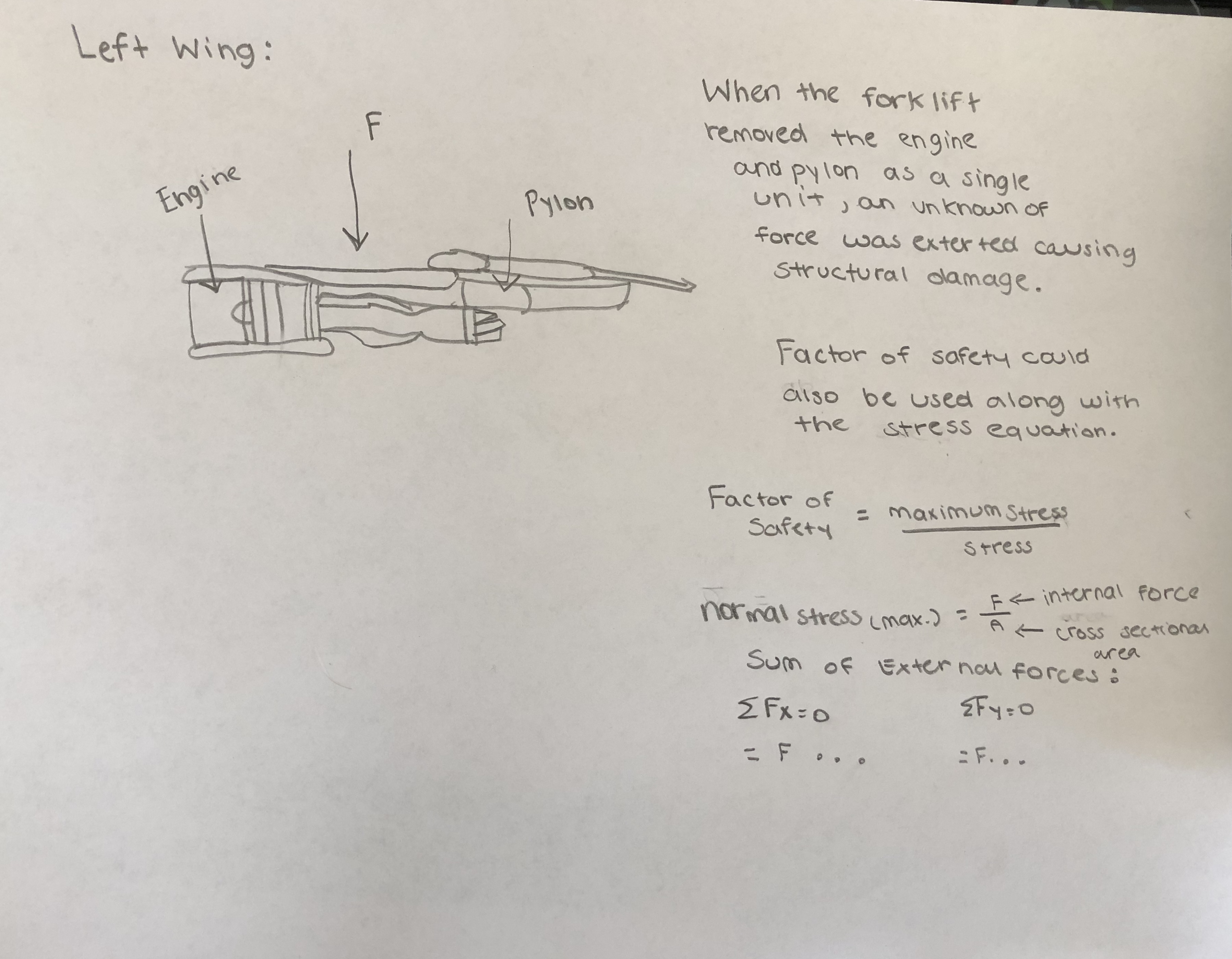

McDonnell Douglas was responsible for the design of DC-10, it was intended for the leading edge slat system to be hydraulically locked when extended. There was no alternate action to lock the slats in place in case of loss of hydraulic pressure to the system. This caused retraction of the leading edge slats. There were also no instructions for removal of the engine and pylon as a single unit in the Maintenance Manual so American Airlines thought of their own procedure to remove and replace the engine/pylon assembly. American Airlines' procedure consisted of employing a forklift to remove the engine and pylon as one. This led to structural damage to the wing/pylon. There was a total loss of 273 people during the American Airlines Flight 191 disaster.

Engineering Perspective

When the engine and pylon was removed as a single unit with the forklift a certain amount of force was exerted onto the engine and pylon causing structural damage. The sum of forces would be an equation to determine the damage done to the engine and pylon. Taking the sum of forces can determine the amount of force the forklift exerted onto the single unit of the engine and pylon. Also, using the factor safety equation into the design of the DC 10 could determine the slats were not going to lock after loss of hydraulic pressure to the system. Some of the limits that were exceeded was the amount of force applied to the engine and pylon. The limits were exceeded because American Airlines maintenance used a forklift to move the materials from the airplane which led to damage to the structures.

Lessons Learned

From an engineering perspective a lesson learned would be to have an informative maintenance manual of the object that clearly informs the removal of each piece of the machine and how to assemble everything back together.

From a personal point of view I learned that the construction of the machine is very critical and having alternative paths for parts of the machine should be taken into consideration just in case the part does fail. Another lesson is to never make flaw assumptions about safety.

The disaster changed the engineering design process by ensuring there is design for safety critical components or systems in case failure mode does occur and the design to ensure safe configuration.

Resources