MEGR 2156

Maggie Wyatt

Sophomore Mechanical Engineering Student

| Home |

About Me |

Assignments |

|---|

Problem Statement

In ENGR 2156, Sophomore Design, I would like to design a lipstick container. I want to change the design of a lipstick container to make it more user friendly. However I want the design to be compatible with the current size of lipstick. I want to change the design, because currently lipstick tubes are still similar shaped to the original design. The only thing different is the dimensions, or look of the container. However they are still operated the same way, by twisting from the base and pushing the product to the top.

My design will start from the current design of lipstick tube and modify it. Once you use the lipstick, there is still a small amount left that you can not use without attempting to take it out of the container. This causes product waste, because you can not use all of the product in the container. This problem also happens in chapstick tubes. If the design was changed to have no waste, or less waste, then the consumer would be able to get more for their money.

Lipstick containers only purpose now is to incase the lipstick, and they are made aesthetically pleasing. However, I want to change it so the container itself improves the use of the product itself. The container should allow for ease of use, less product wasted, and protecting the product itself.

Restraints I have in the design would be the cost of manufacturing. As the cost would need to be cheaper or equal to the current manufacturing process. Also, the design has to be able to be easily held in the hand and applied. Another restraint is the amount of time I have to come up with a design. I want the size of my design to be compatible with the current design, therefore the dimensions must be similar, and able to hold the average lipstick bullet.

Assumptions

One assumption is that the user has to be able to work the product themselves by hand without any power from an electrical source. Another assumption is that a lipstick bullet is .5 in diameter, cylindrical shape, and 2 inches long. Also that the lisptick bullet is just the product itself, that my design will be the entire packaging.

Gantt Chart

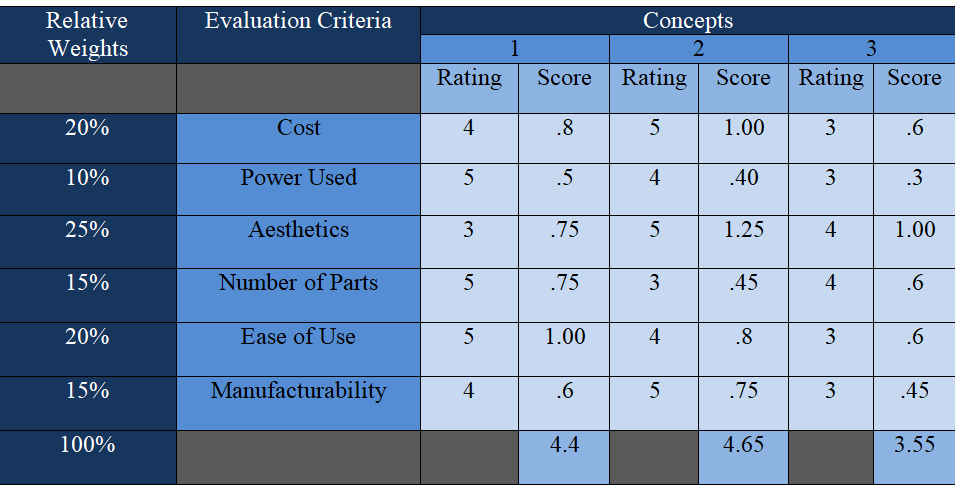

Decision Matrix

In my decision matrix I directly compared my different concepts from Assignment 3 by a set of criteria with a variation of weighting. The two criteria I weighed the heaviest were Aesthetics, then Cost and Ease of Use. The reason aesthetics were weighted so heavy is because makeup packaging is designed with a purpose to hold a product, but the look of the packaging plays a large role when choosing a product. Cost was a large factor as a company would not want to use this form of packaging if it will cost them significantly more than their current design. Ease of Use was also weighted heavily as the product is designed for the consumer so the packaging must be easy to open and use. The Concept that had the best score was concept 2. This concept focusing on having the outside casing push down over the inside casing.

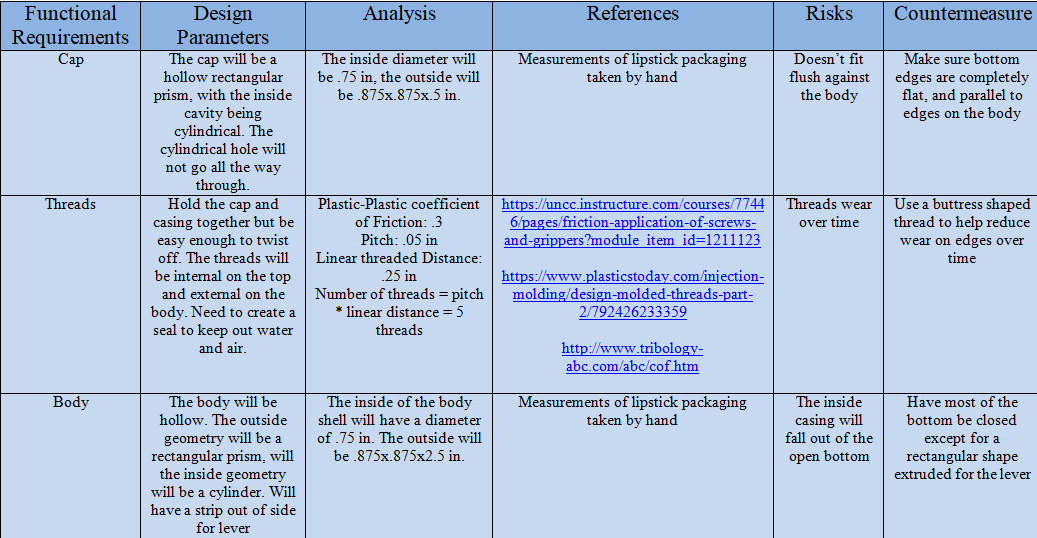

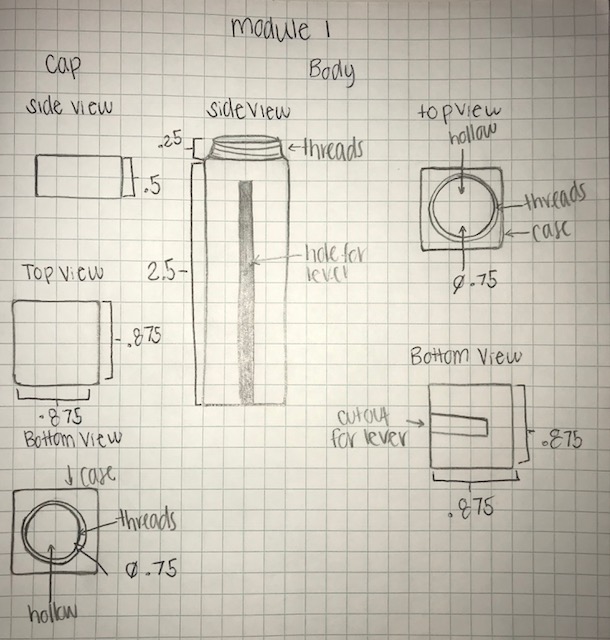

Module 1: Outside Casing and Cap

Module one focuses on what you can see from the outside. It is a subassembly of the cap and the outside body which are connected by the threads.

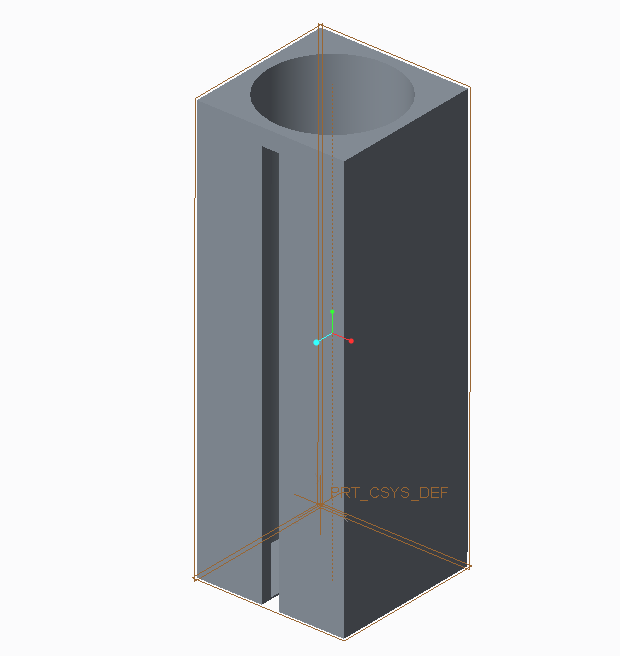

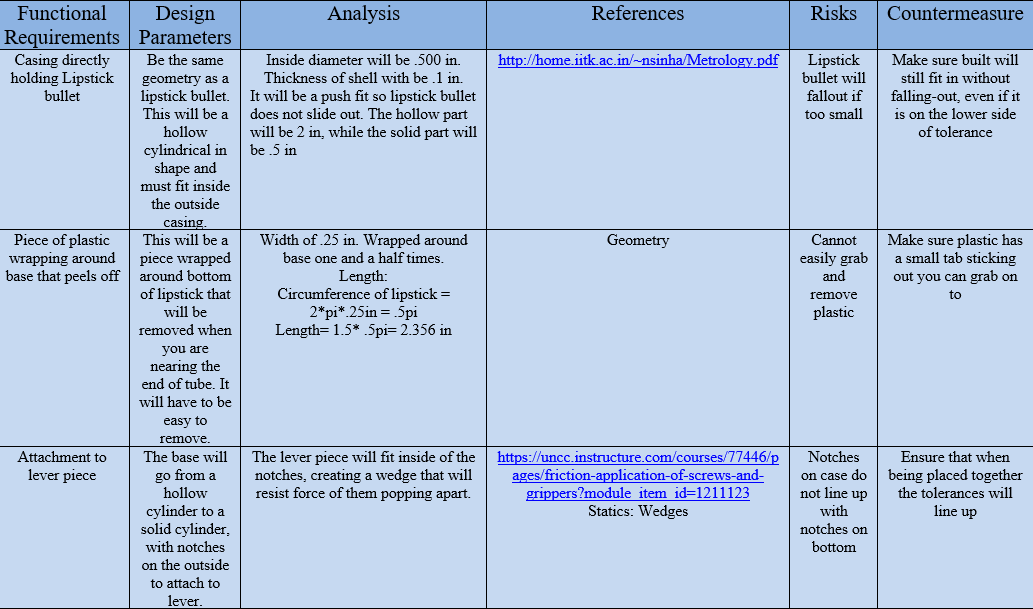

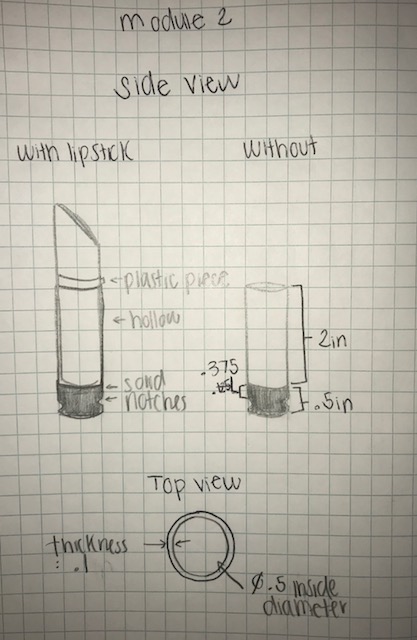

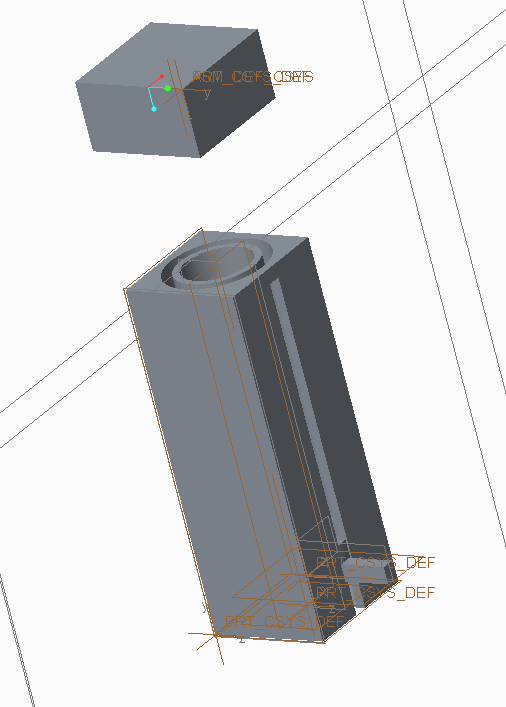

Module 2: Inside Casing

Module 2 is the inside casing the will hold the lipstick bullet. There will be a small piece of plastic around the end of the lipstick, which can be removed at the end to allow for new product.

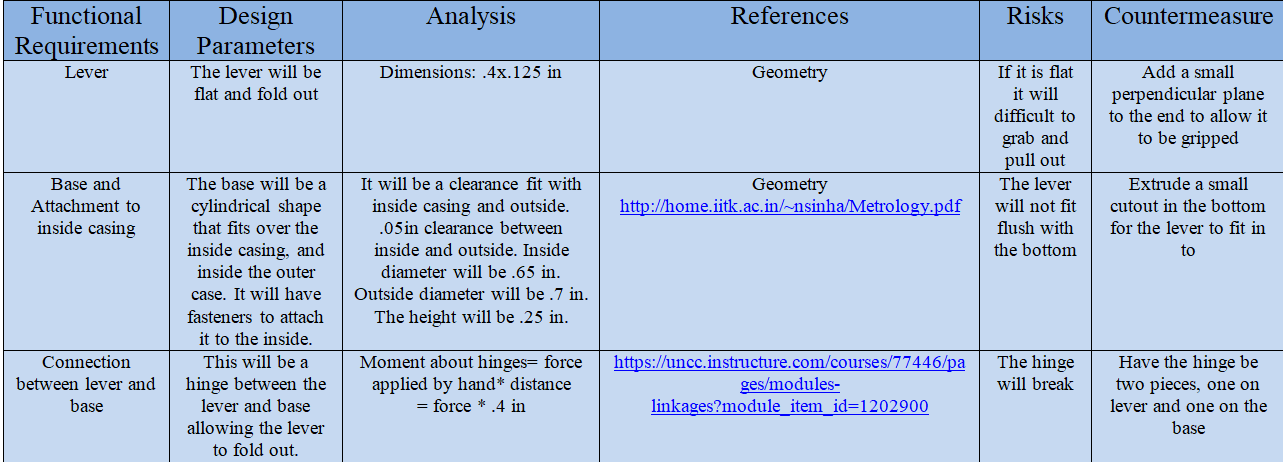

Module 3: Lever Assembly

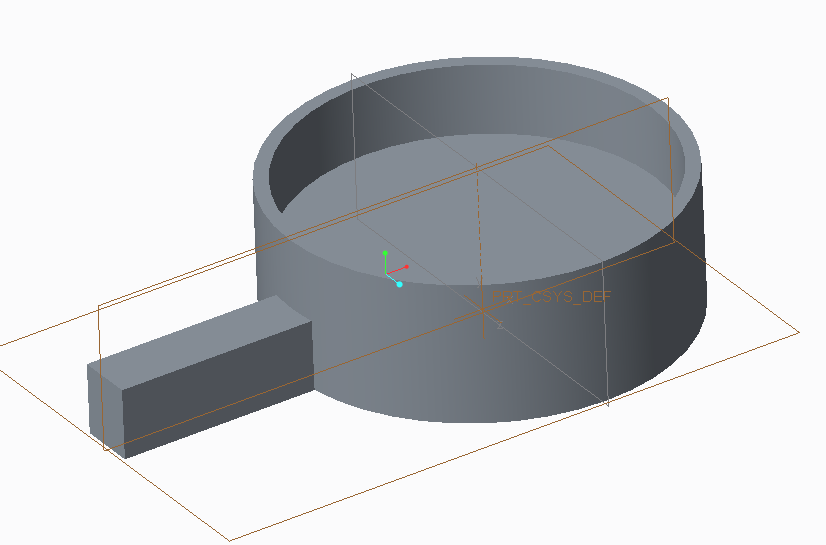

Module 3 focuses on how the product is pushed up. There will be base that will attach to the inside casing, with a lever that folds out and it used to push up product.

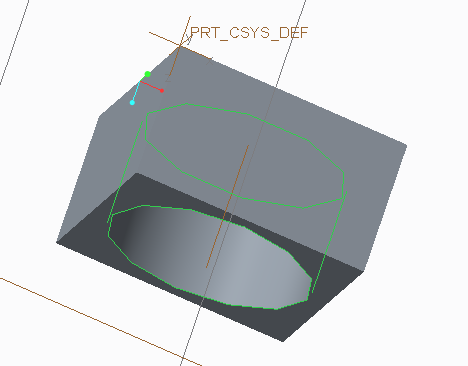

Creo Assembly

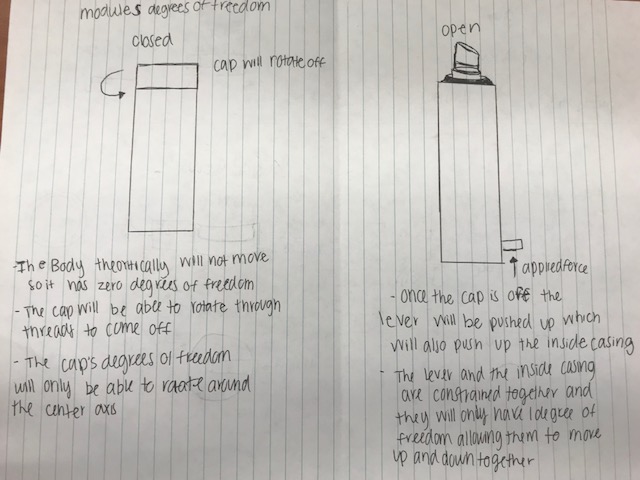

Degrees of Freedom of Assembly

My design moves based off force applied to the lever by the hand. The power would depend on the amount of force you apply to the lever. If you apply .5 Newtons of force, over the 2.5 inches of the design, in 3 seconds, you would create .4166 Watts of power.

Links to Creo Files

Creo is a form a parametric modeling. It is used to create 3D parts. Your parts must be fully constained dimensio wiser, and when creating an assembly they must be fully constrained.

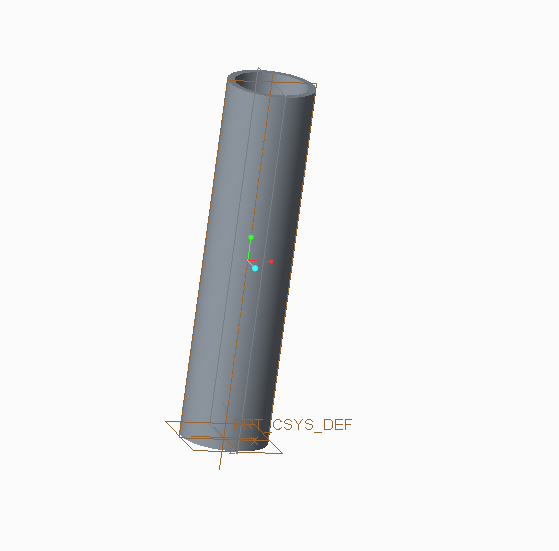

Assembly Cap Body Inside Casing Lever

Lessons Learned

In Assignment 4 I learned how to take my individual aprts on creo and assemble them. I also learned about clearances in manufacturing and how they depend on the tolerances. I also did reseach on the different types of fits in order to have the dimensions and fits on my parts be correct.

Date and times

-Made Decision Matrix: March 15th, 2018. 8-9:30am

-Came up with modules: March 15th, 2018. 9:30-10am

-Did hand drawings: March 15th, 2018. 10-10:30am

-Finished frdparrc tables: March 15th, 2018. 10:30am-2pm

-Updated problem statements and assumptions: March 16th, 2018. 10-11am

-Updated Webpage: March 16th, 2018. 10-11am

-Made Creo Drawings: March 16th, 2018. 10am-12pm

-Made hand drawings of assembly and degrees of freedon: March 19th, 2018. 4-4:30pm

-Comment to Advisees: March 19th, 2018. 4:30-5 pm

-Finished Webpage: March 19th, 2018. 5-5:30 pm

Comments to Advisee

Lindsay Ward

Comments

Webpage not posted in time to make comments 3/19/2018 5 pm

Marc Duemmler

Comments

-In the problem statement why did you pick 3 kg as a weight?

-In your decision matrix maybe explain what each concept was, or make a link to assignment 3 so some one could easily view your concepts

-Along with that, say which concept was the best by your matrix and what was special about that concept

-Maybe consider rearranging your diagrams for each module so they visually look better together

-You could mention how each digit in your hand is connected to each other