Drawings

Problem Statement

Innovation is needed on the frontlines of space. Better maneuverability must be ensured for the analysis and data we want to find. An extraterrestrial drilling

rover needs to have the best movement to get out of risky mining sites. It is important to strategize and contemplate on the best way to find new resources on

other planets too dangerous for humans. My design will suspend future rovers in the air both safely and effectively. These designs must not fail under any circumstance when being used.

The safety and mobility will be secured through many safety checks. Suspension on rovers will be further ensured through strategizing on the best material to make it out of.

Assumptions

Starting assumptions include the weight of the overall vehicle on the suspension, the manufacturers are experienced in assembling the components,

and the material is not determined but will do the job. The electrical wires are added after the suspension is assembled.

The parts manufactured will be made of the correct material and measured tolerances.

Created drawings are readable and easy to follow in the machining process.

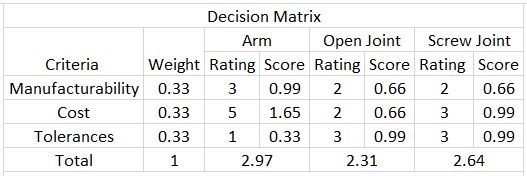

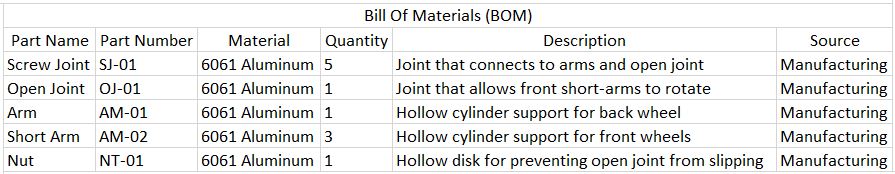

Decision Matrix

In this new decision matrix layout, I chose manufacturability, cost, and tolerances to discover the most critical part of the suspension. Manufacturability measures the difficutly it will take to machine a part.

Cost varies the overall expenses the part is. Lastly, the tolerance row measures the part's number of tolerances it needs. Five being the hardest to process, one being the least worry.

It is clear the arm of the suspension is going to be the part that requires the most attention. While it does not have tolerances, it is very expensive compared to the other parts.

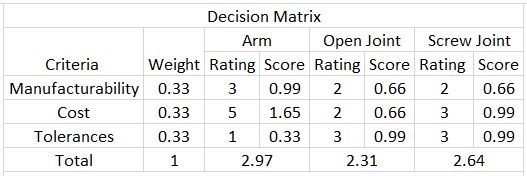

Rocker-Bogie Suspension

Assembly

Major Component Drawings

Screw Joint

Drawing1

Open Joint

Drawing2

Arm

Drawing3

Assembly

Drawing4

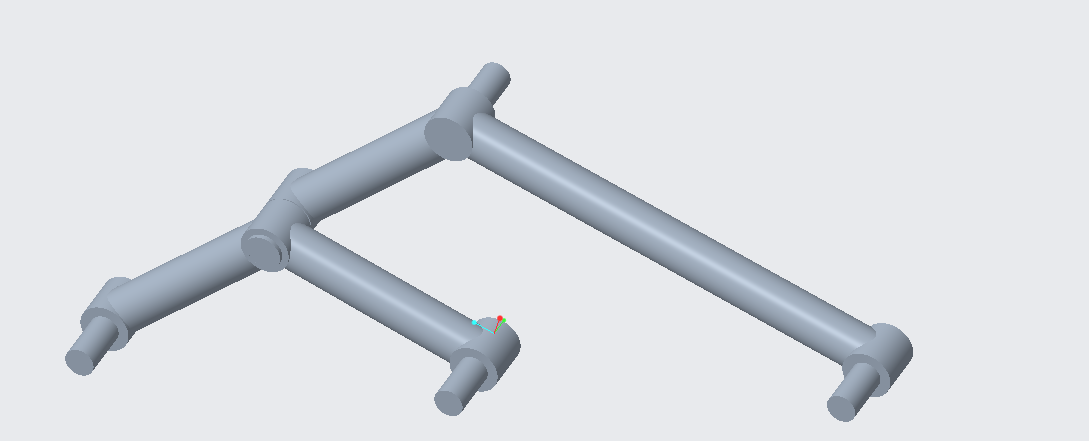

Bill Of Materials

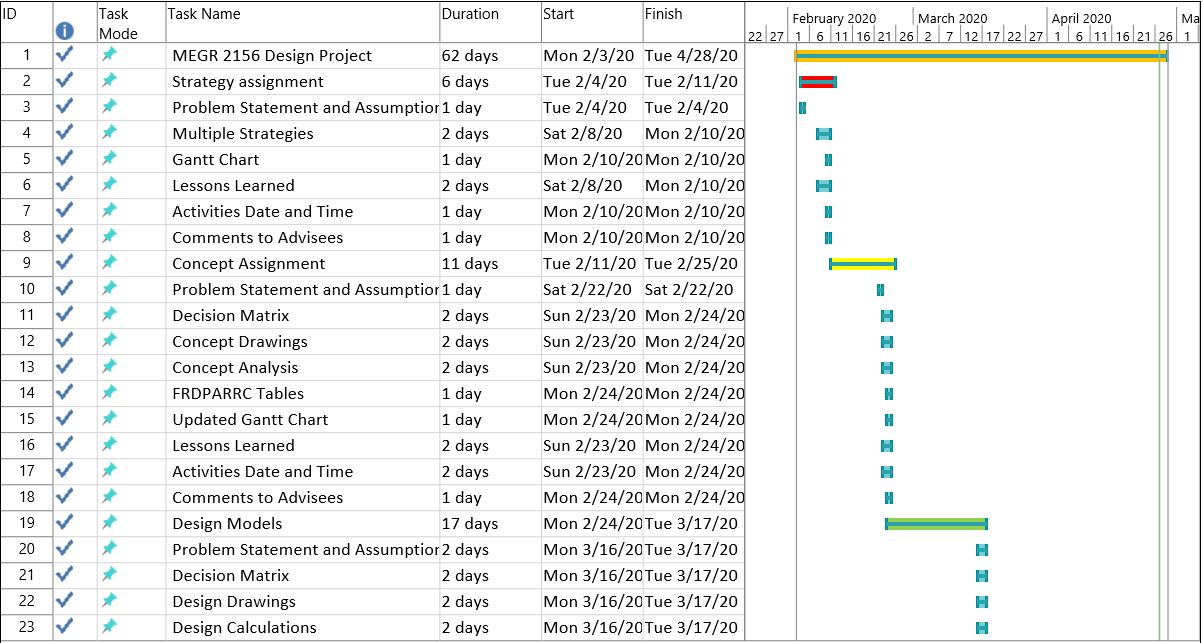

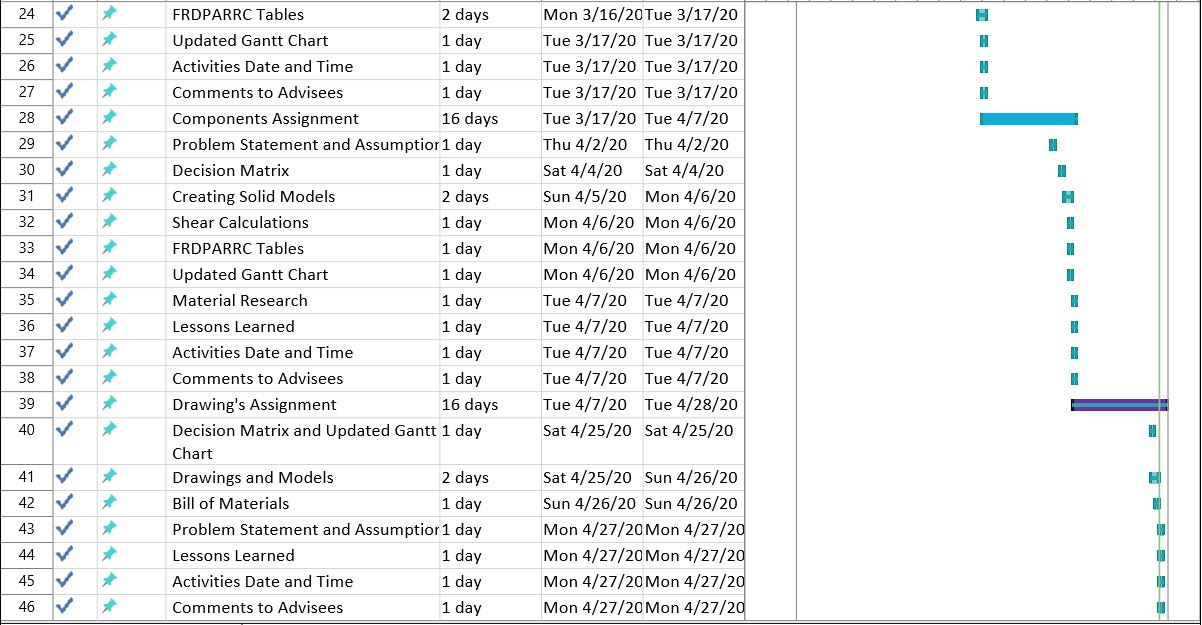

Completed Gantt Chart

Lessons Learned

Since the beginning of the semester, I never knew how many hard yet productive hours I would put into this design project. I have learned and understood that working ahead on the assignment will result in less tiring hours and more restful sleep.

Within this drawing assignment, I learned that I enjoy using creo even if it is a bit frustrating sometimes. I understand how to make a bill of materials and create drawings using creo.

Listing all the bits and pieces for a manufactured assembly is very important.

Activities Date and Times

04/25/20- 1 hour: Updating Decision matrix and Gantt Chart

04/26/20- 3 hours: Creating Drawings

04/27/20- 1 hour: Bill Of Materials

04/27/20- 1 hour: Updating Problem Statement, Assumptions, Lessons Learned, Activities, and Comments to Advisees

04/28/20- 2 hours: Coding it all into the website

Comments to Advisees

Christof

Superb drawings! Great layout and bill of materials. I see no major issues, well done.

Erica

Everything looks great. Drawings are clear and the webpage has a good layout. The poster is very nice. One tiny issue with the gantt chart, it is hard to read. Other than that it is awesome. Have a great summer!

index