Assignments

Assignment #5: Components

Updated Problem Statement:

Design an instrument for a more effective transfer of laundry from the washer to the dryer. This device, of a selected model, will contain the ability to fold clothes, too. This device should allow for a quicker way to complete house-hold chores without having to be present in the case that everyday life gets in the way. The automatic transfer and optional folding of laundry will eliminate the issue of worrying about soaking clothes that have been forgetten in the washing machine all day. The machine will have automatically retractable arms with mesh baskets attached that make for an easy scoop and transfer. Another specification is that it can be programmed to perform for both top and front loading washing and drying machines. The machine will also have an additional programming option to fold the laundry once it's dried. This device should be manufactured so it can be easily used, assembled, and cleaned by any able-bodied persons of an independently functioning age.

Assumptions:

The functionality of this device is important to the overall effectiveness that it will provide to users.This device should have impeccable grip strength as the design selected will have the ability to fold clothing once the laundry duties are complete. This being said, the Grip Claws that will be placed on either side of the device, acting like human arms and hands, should be highly mobile so that articles of clothing of any materail, shape, or size will not generate issues for the machine, making this a highly desirable product for households and businesses all across the world. It should be safe, cost efficient, and generate desired results at quick speeds.It should be cost efficient and safe for every day use.

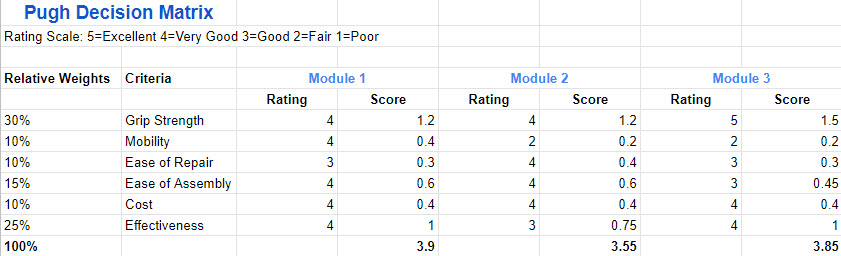

Pugh Decision Matrix

The Pugh Decision Matrix above considers all of the possible Modules that were designed for this machine. Each of the modules contains a differing claw that have similar functionalities but different levels of preciseness and overall effectiveness. The selected Module was Module 1, given that it contains the highest overall score in the Pugh Decision Matrix. The most heavily weighted category in the decision matrix is the grip strength, and with careful design and consideration, although Module 1 is not the highest rated in that category, it is effective enough to move forward with the design.

Components

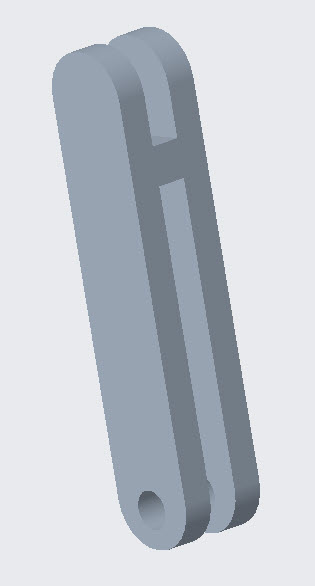

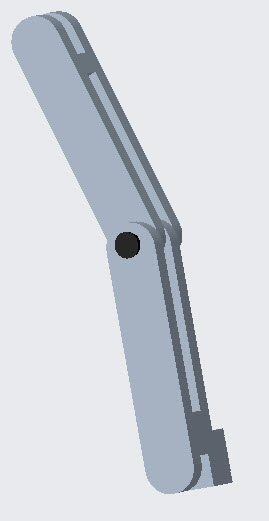

Component 1

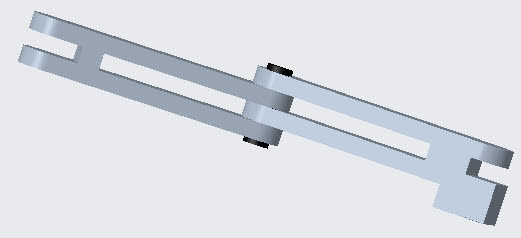

This component is the base end of the retracting arm. It is what connects to the actual machine and allows for the mobility of the claw. With the connector towards the base of the component, stability is created and allows the designed claw to be able to carry and grip heavier loads without concerns of it breaking due to lack of strength. The holes that have been driven through the opposite end of the component allow for the connection to the other components to this machine's grip claw which are specified and displayed in the descriptions and pictures below.

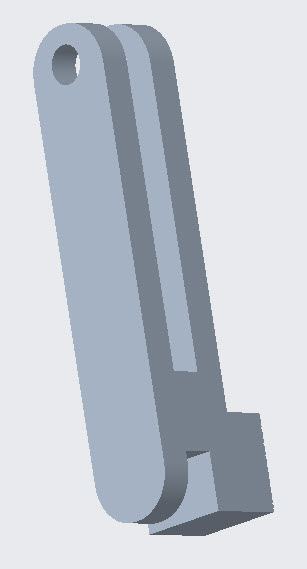

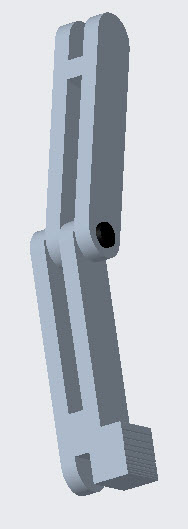

Component 2

This component is the most important of the three displayed in this part of the model because it is what actively initiates and performs the grip of the clothing for folding purposes. There is a strategically designed grip part that is attached and connected to the end of the component that is what allows for the clamping mechanism. As the previous componet contained, there is a support bar connecting both sides of this component that allows for strength support. With through holes that run through the part measured at the same distance and diameter as Component 1, these holes are designed to line up to allow for connection with the use of Component 3.

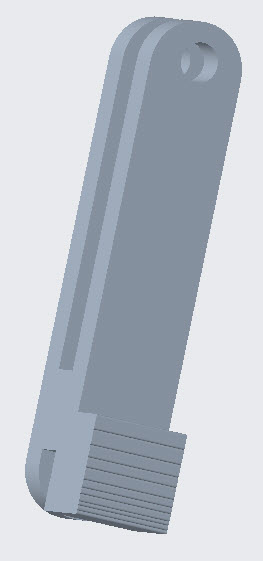

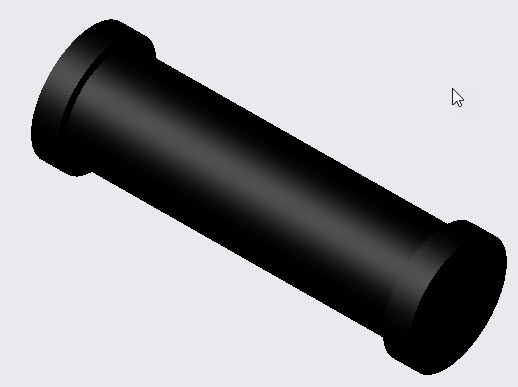

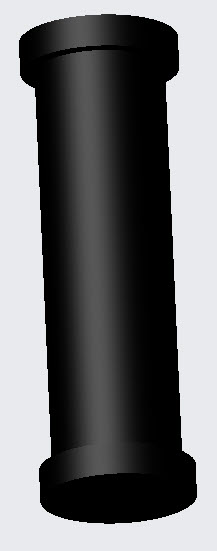

Component 3

Component 3 consists of a silicon pin that allows for fluid mobility and strength in order to keep the other components in tact. It is removeable at one end and simply snaps into place once inserted through the holes of the other two components. This piece is easily removed and replaced if needed due to continuous use and material wear.

Assembled Model

FRDPARRC Tables:

FRDPARRC Tables (Components 1-3)

Calculations

Updated Gantt Chart:

The above link is the Gantt Chart for this project. As the semester progresses, the chart will be updated.

Lessons Learned

- I learned that it's important to factor tolerances on my CAD models.

- I learned that when assembling components I have to pay closer attention to what axis I assemble on.

- I learned how to depict which areas of my design needed tweaking to enhance the product.

- I learned how to better sketch and extrude CAD models.

Activities Date and Time

- Updated Problem Statement 11/25/20 1-2pm

- Updated Assumptions about the Problem 11/25/20 12-12:30pm

- Analyze each component and understand how they work together 11/26/20 - 11/28/20

- Created a Pugh Decision Matrix for each Module 11/26/20 10:00am

- Update CAD modles 11/27/20 - 11/30/20

- Analyze the best way to create the most mobility 11/28/20 8am-11am

- Regenerated FRDPARRC Tables 11/29/20 6-7pm

- Added Assignment 5 to Gantt Chart 12/01/20 12-12:15pm

- Viewed Nate Hardy's Webpage 12/03/20 10:00am

- Viewed Philip Brown's Webpage 12/03/20 10:15am

- Final update and check-through of Assignment 5 Page 12/03/20 11:30am

Comments for Nate Hardy

- I think the components used are well represented and its easy to understand how they work.

- Based on your analysis of each Module and Component I think that you selected the best option.

- Your final model will be interesting to see because your project has come together super well so far!.

- Good job, Nate :-)

Comments for Philip Brown

- I appreciate the simplicity of your page. It's very easy to maneuver.

- Your components are well represented and the analysis of each makes your design easy to follow.

- Your calculations seems to be representitive of the functions of your design which is important to the final result.

- Your descriptions are thorough and I believe your final product will turn out great!