About Luke Sewing

My name is Luke and I am pursuing a degree in mechanical engineering. I graduated from CPCC with an associate’s degree in engineering and transferred to UNCC in the fall of 2020. I have always enjoyed working on any electronic or mechanical items such as RC airplanes, drones, and robotics. I really enjoy the 3D design aspects of mechanical engineering and have a good bit of experience with Solid Works and Fusion 360 since I do a lot of designing for my job and my own pursuits. I enjoy making things and have built two 3D printers and a CNC machine. Also, I own a 1944 South Bend Heavy 10 Lathe. I enjoy spending time machining and 3D printing things that I have designed. I am studying mechanical engineering because I have always been fascinated with mechanical machines. As a boy I would take apart and rebuild or fix anything and everything that I could get my hands on. I am very excited to take classes that are directly related to my field and learn more design techniques and machining.

There are three engineering designs from the past 150 years that have been prevalent factors in my own decision to pursue mechanical engineering, along with the great impact they have had on our present world. The first of which would undoubtably be an airborne design by the Wright Brothers. They are recognized as being the first to enter the world of manned flight as we know it today. There is so much engineering that went into their design, including the creation of a wind tunnel of which the concepts are still in use today. In 2020 it is quite common to look up at the sky and see an airplane passing overhead. This goes to show you how relevant this invention was to our modern society, as it now facilitates travel and the exchange of goods all over the world in a rapid manner. As a boy watching and reading things on these pioneers of the sky was one of my favorite things to do and later led to me learning to make radio-controlled airplanes.

Even more recent is the invention of the microprocessor. It is hard to believe how just ones and zeros could have such a profound influence on the world. From a simple calculator to the cell phone, this device has helped shape the world as we know it by allowing the creation of many electronic devices. Certainly in my own life it has enabled me to learn so many things that would have been out of grasp without this incredible technology.

The newest invention that definitely has changed and is changing the world is 3D printers. Personally, they have been of great influence on my life and career choice, aiding me in deciding that mechanical engineering was the best degree for me to pursue. These machines have made available to the everyday person the ability to make plastic parts and they have led to an increase in the use of additive manufacturing in the industrial sector. Companies now have the ability to 3D print metal parts as opposed to machining everything, which opens entirely new levels and abilities in the design stages of product development, having particular benefits in the aeronautical field. Buying and building my own 3D printers has taught me so many things from electronics to 3D design. Without these incredible inventions I would not be where I am today.

Product Design Analysis of Anderson Power Poles:

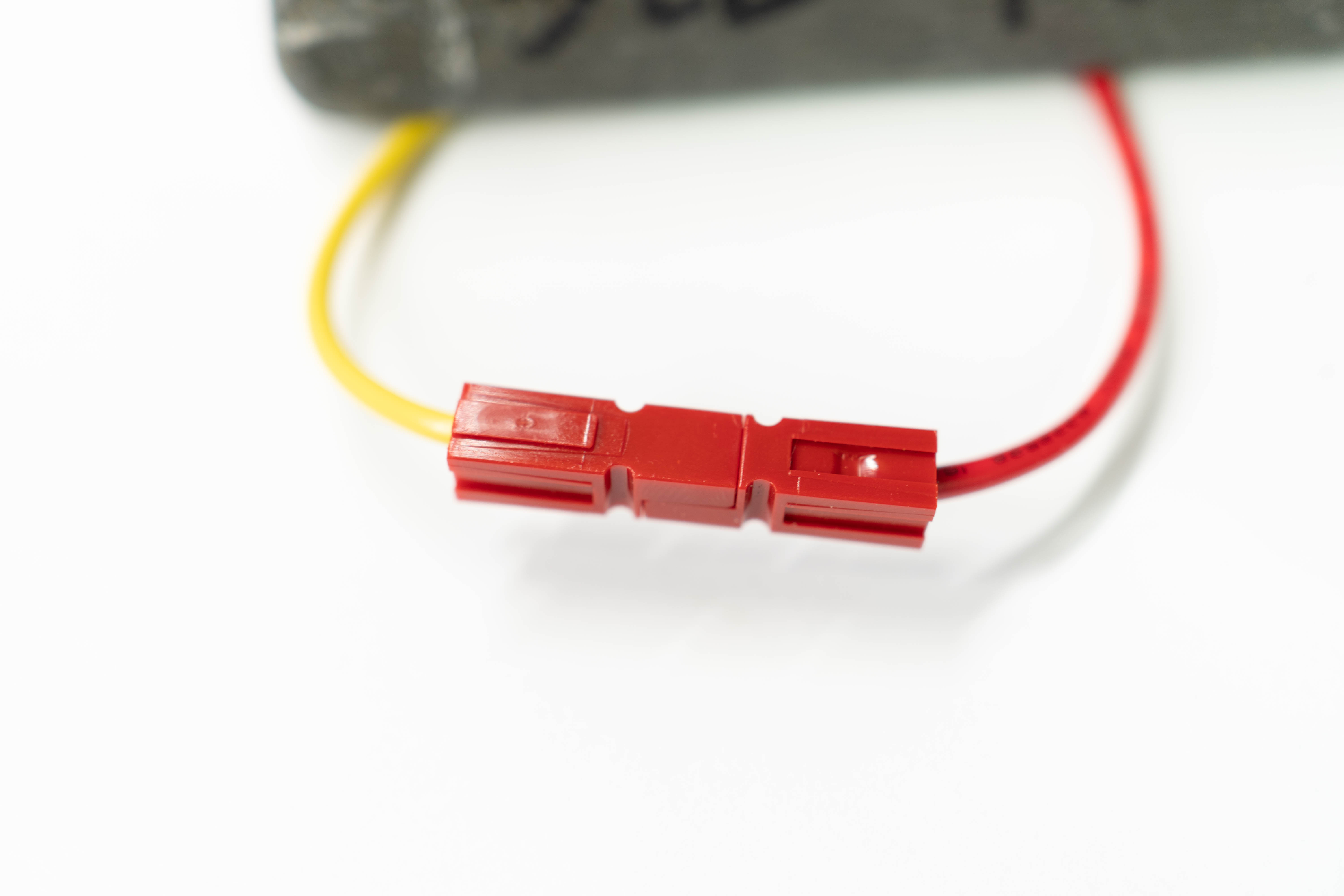

The Anderson Power Pole connector is used widely by many electronics hobbyists and amateur radio operators, making it a common item in my home. The modular design enables a wide range of applications along with a range of options for various current ratings and colors. An active patent is currently held by Anderson Power Products Inc. and the inventor is Danna A Mancini.

Patent found here

Geometry:

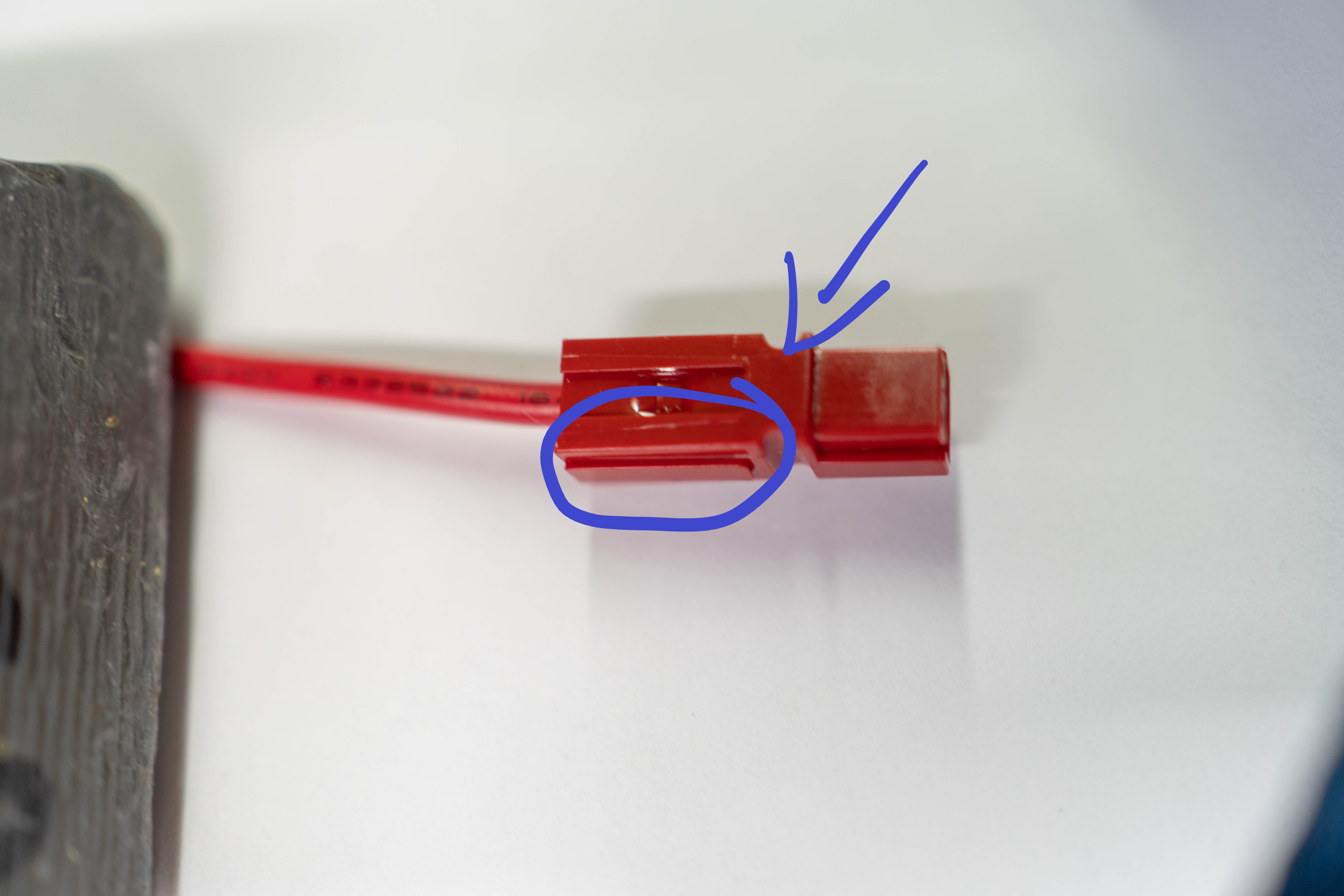

Each connector has a male and female tab on the side that allows them to be pushed together for a snug fit.

There is also a pen hole so that a pen can be inserted for a more permanent mate.

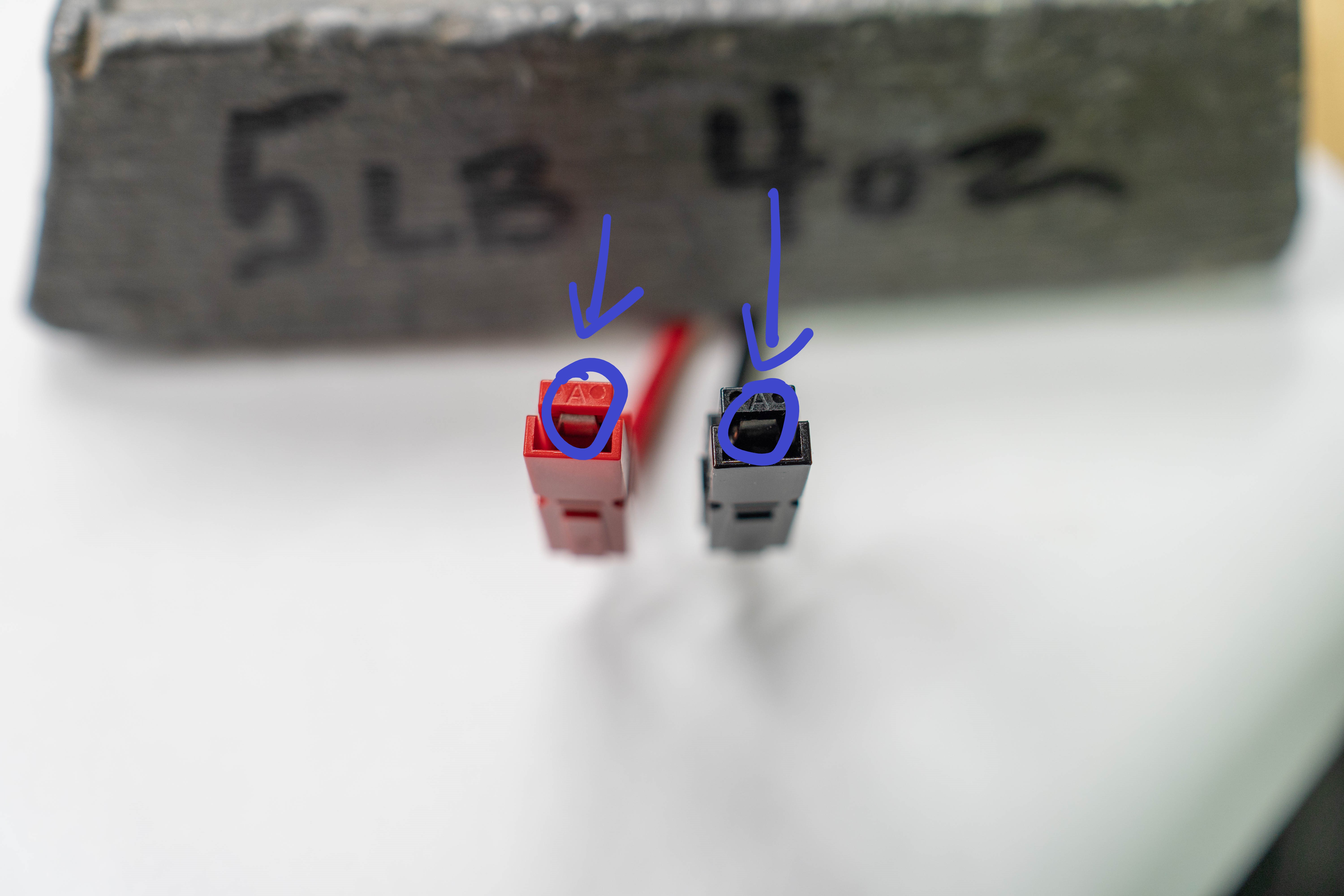

Inside the connector there are metal tabs that allow the metal crimp on parts to be snapped in place.

The design allows for two connectors to snap together providing a solid connection with low resistance.

Alternative Materials:

If made from aluminum, the connector would not function as intended. Instead, since aluminum is a conductor, it would defeat the purpose of the connector because it would cause a short in the connection as the two connectors were joined.

A feasible alternative material to make these connectors from could be polytetrafluoroethylene (PTFF). PTFF has both strength, heat resistance, little to no conductance and self-lubricating properties. This might be a good solution to combat overall wear through the life of the connector. This material would also allow for injection molding which could prove a very cost-effective way to manufacture them.

Alternative Products:

Arcless power connector, patent found here

SBS connector, patent found here

Manufactured:

These connectors are manufactured by Anderson Power Products, Inc. in Sterling, Massachusetts through injection molding.

Problem Solution for MEGR 2156:

While I have have always enjoyed building any kind of radio-controlled vehicle, one particular genre of vehicles that I like are tracked vehicles. The issue when building this type of vehicle always comes down to the tracks. These are doubtless the hardest thing to get right and buying premade tracks that are of a reasonable size and strength can be quite costly. In this class I would like to solve this problem, by creating a design utilizing inexpensive serpentine car belts and 3D printed spacers to create an affordable and robust DIY track design.

I spent between 4 and 5 hours creating this site and writing the material.

You can contact me at my email by clicking this link.