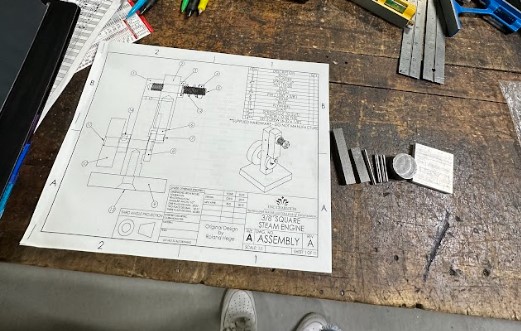

Machining Lab

For our sophemore design course here at UNC Charlotte, we were required to manually machine a small-scale air engine that we had designed in a previous semester using provided drawings. Tolerances were to be strictly followed to ensure that this engine would work under certain air pressures at the end of the semester. Here is a culmination of pictures detailing my process of machining this air engine from start to finish.

Figure 1: Raw materials

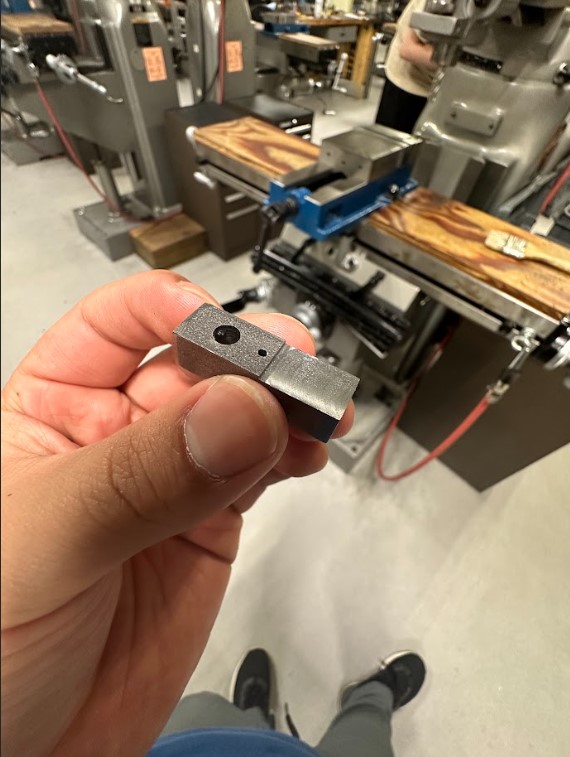

Figures 2-4: Body

Figures 5-7: Cylinder

Figure 8: Spring cup

Figure 9: Stud

Figures 10-12: Piston

Figures 13-17: Crankshaft

Figures 18-19: Base

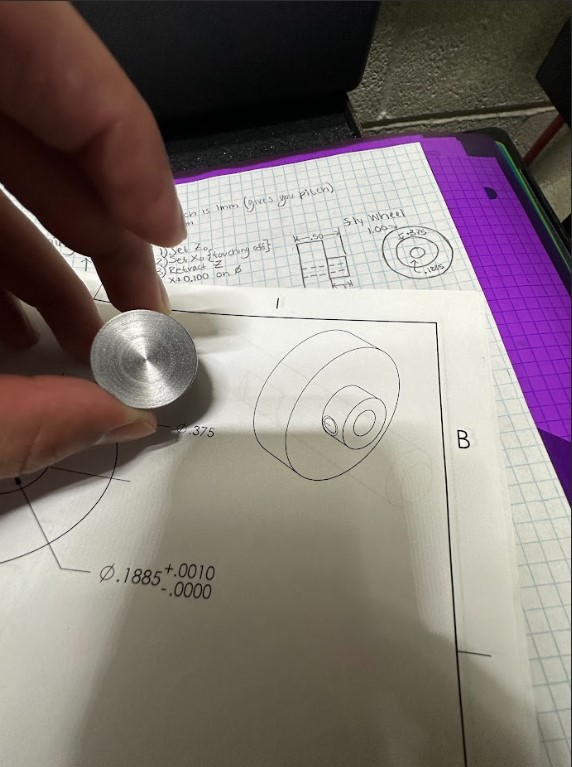

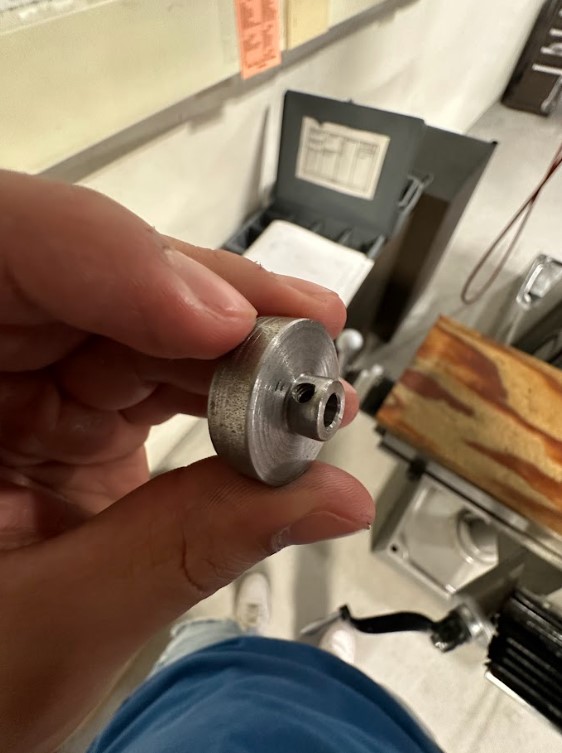

Figures 20-22: Flywheel

Figures 23-28: Assemby

Air Engine Drawings