Research Themes

The research activities are on Advanced Manufacturing, in particular on Digital and Sustainable Manufacturing.

DEAM LAB's main research themes are presented below.

This theme includes the following topics:

- Industrial Internet of Things (IIoT)

- Big data

- Artificial Intelligence & Machine Learning

- Physics-Based Modeling

- Cloud Computing

Digital Twins

Digital Twin (DT) is the creation of a digital representation of a real-world physical asset (system, process, or product), to enable management, simulation and optimization. They integrate real-time data from sensors (IoT), Artificial Intelligence (AI), physics-based modeling and control systems to adapt to changing conditions such as, product defects, machine breakdowns or supply chain disruptions.

DEAM Lab is working on five key topics related to the development and deployment of DTs in manufacturing, described as follows.

1. Manufacturing Processes and Systems Simulation and Optimization. DTs are used for simulating and optimizing manufacturing processes and systems for improving product quality, productivity and efficient use of resources.

Example of a Digital Twin of Industrial Automation (Source: YouTube)

2. Components Repair. DTs are revolutionizing repair practices in industries such as aerospace, energy, and defense. By creating digital replicas of components and systems, DTs allow the automatic repair of components by integrating defect detection, generation of CAD models of defective parts, creation of toolpaths for hybrid processes (i.e. metal deposition by Additive Manufacturing (AM) and finishing by machining), conducting hybrid processes and final inspection. This approach is essential for streamlining the repair process, thereby improving the overall efficiency of the repair system.

3. Process monitoring and maintenance. DTs in manufacturing integrate data from sensors implemented in the processes (such as AM or machining) and AI to monitor performance in real-time. These DTs allow real-time quality control by fast detection of defects or deviations during production and establishes proactive maintenance schedules to identify potential failures before they occur, thus reducing downtime.

This theme includes the following topics:

- Material Constitutive Modeling

- Finite Element Simulation

- Analytic-Based Modeling

- Physics-Guided Machine Learning

- Hybrid Modeling

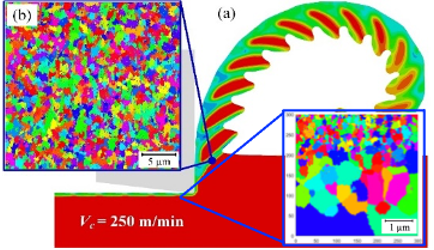

Multi-physics/multi-scale modeling, simulation, and optimization of manufacturing processes

The importance of multi-physics and multi-scale modeling, simulation, and optimization of manufacturing processes has grown significantly. These approaches deepen the understanding of physical phenomena and enable more accurate predictions of process performance and part quality.

This theme includes the following topics:

- Workforce Development

- Workforce Guidance

- VR/MR in Education

- Product Design

- Layout Planning

Immersive Technologies in Manufacturing

Immersive technologies is an integration of virtual content with the physical environment in a way that allows the user to engage naturally with the blended reality.

eXtended Reality (XR) is an umbrella term used to describe all the immersive technologies that can merge the physical and virtual world. XR encompasses:

The integration of Digital Twins (DTs) and eXtended Reality (XR) technologies enables the creation of Immersive Digital Twins (IDTs). IDTs are interactive digital replicas of manufacturing processes and systems, used for simulation within XR environments, offering users a more safe, immersive, engaging, and realistic training experience. At the DEAM Lab, these IDTs are being developed to support remote teleoperation of manufacturing processes and systems, and enhance workforce training in manufacturing.

1. Remote teleoperation of manufacturing processes and systems using Immersive Digital Twins (IDTs). IDTs are particularly well-suited for the remote teleoperation of manufacturing processes and systems in hazardous environments, such as nuclear and chemical facilities. Videos below demonstrate examples of IDTs used for the remote teleoperation of a CNC milling machine and a intelligent Robotic-Assisted Finisher System (iRAFS), offering an immersive experience with real-time video and audio streaming, as well as bidirectional communication between the physical machine and its digital counterpart. This project is developed in collaboration with Centria University of Applied Sciences in Finland.

IDT for remote teleoperation of CNC Machines1

IDT for remote teleoperation of an Intelligent Robot-Assisted Finisher System (iRAFS)2

1. T. KAARLELA, J.C. OUTEIRO, A Cyber-Physical Machine Tool Concept for Education and Workforce Training in CNC Machining, 53rd SME North American Manufacturing Research Conference (NAMRC 53), Clemson University. Greenville, SC, USA, June 23 - 27, 2025. Manufacturing Letters (accepted).

2. J.C. OUTEIRO, T. KAARLELA, N. UÇAK, N. GREIS, H. CHERUKURI, Development of a Digital Twin of an Intelligent Robot-Assisted Finishing System for Polishing Metal Additive Manufactured Components, 8th International Conference on Integrity, Reliability and Failure of Engineering Systems and Materials (IRF2025), Porto, Portugal, 15-18 July, 2025.

2. Workforce development using IDTs. IDTs can also provide personalized, on-demand, safe, immersive, engaging, and autonomous training. IDTs allows real-time, contextual guidance tailored to specific tasks and environments; continuous learning and adaptation; multimodal interaction through voice and visual communication; and immersive simulations for skill practice in safe, controlled settings. Below you can find some examples of IDTs for education and workforce training in manufacturing

Example of a IDT for education and workforce training in Additive Manufacturing of ceramics3

Example of a IDT for education and workforce training in CNC Machining4

Example of a IDT for education and workforce training in GD&T5.

3. Project Title: Immersive Training for Additive Manufacturing of Technical Ceramics using Mixed Reality. Funding: CAMAC. Period: 2024.

4. T. KAARLELA, J.C. OUTEIRO, A Cyber-Physical Machine Tool Concept for Education and Workforce Training in CNC Machining, 53rd SME North American Manufacturing Research Conference (NAMRC 53), Clemson University. Greenville, SC, USA, June 23 - 27, 2025. Manufacturing Letters

5. Project Title: Workforce Training for Metrology using Immersive Technologies. Funding: CPM Affiliates. Period: 2023-2024.