Team

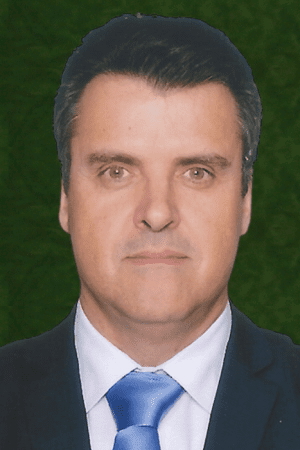

José C. M. Outeiro, Ph.D.

Full Professor

DEAM LAB DIRECTOR

Bio:

Professor José C. M. Outeiro is researcher and educator with a career in Mechanical Engineering, particularly in the field of Advanced Manufacturing. He holds a full professorship position at the University of North Carolina at Charlotte.

Throughout his career, he has held positions at various institutions across Europe and the United States. These include appointments at the Arts et Metiers Institute of Technology in France, Karlsruhe Institute of Technology in Germany, the University of Kentucky in the U.S.A., and the Catholic University of Portugal. He was awarded Fellow of the esteemed International Academy of Production Engineering (CIRP).

Dr. Outeiro has expertise of over 25 years in machining and hybrid processes, especially focused on the quality of the product concerning the surface integrity, part distortion and the functional performance and lifespan of components. He has developed a strong expertise on process modeling using multiphysics/multiscale approaches and Machine Learning to be integrated in Digital Twins (DTs).

Professor Outeiro's actively contributes to the scientific community by serving on editorial boards of renowned journals and scientific committees of conferences. He has also mentored numerous Ph.D., Master's, and undergraduate students. His achievements have been recognized with several awards and distinctions.