Teaching

MEGR 7090/8090 - 003: Digital Manufacturing

Graduate | Fall 2023, 2024 & 2025

Instructor: Jose Outeiro

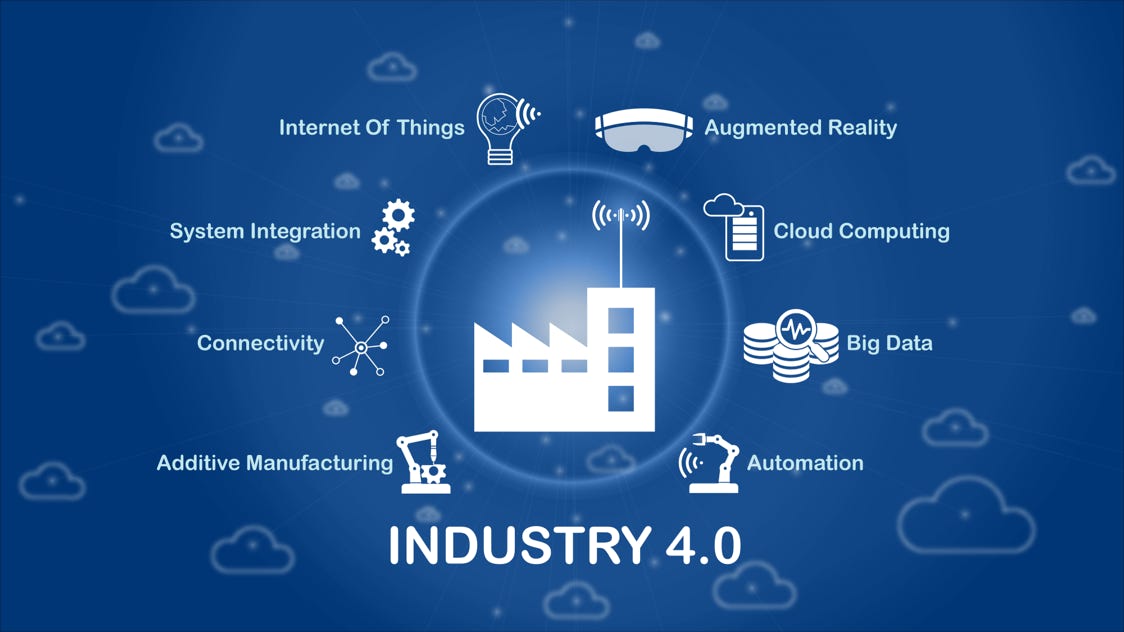

Digital manufacturing is an integrated manufacturing approach that leverages computer-based technologies to enhance the efficiency of manufacturing operations and to improve the quality of products and services. As an integrated approach it links systems and processes across all areas, from design to production and on the maintenance and support of the end products. Examples of such computer-based technologies are: Internet of Things (IoT), Big Data, Artificial Intelligence, Machine Learning, Augmented Reality, Cloud Computing, Advanced Robotics, Additive Manufacturing, and Digital Twin. Digital Manufacturing technologies contributes for the fourth industrial revolution also be called Industry 4.0.

This course on Digital Manufacturing provides students with the opportunity to acquire the fundamental knowledge of computer-based technologies used in manufacturing, and to prepare them for the implementation of such technologies in the industry. Therefore, the students will be better prepared to address the present and future manufacturing challenges, thus to be succeed in today's competitive business market.

MEGR 4098/5098/8892 - Intelligent and Sustainable Machining Processes

Undergraduate & Graduate | Spring 2024 | Fall 2025

Instructor: Jose Outeiro

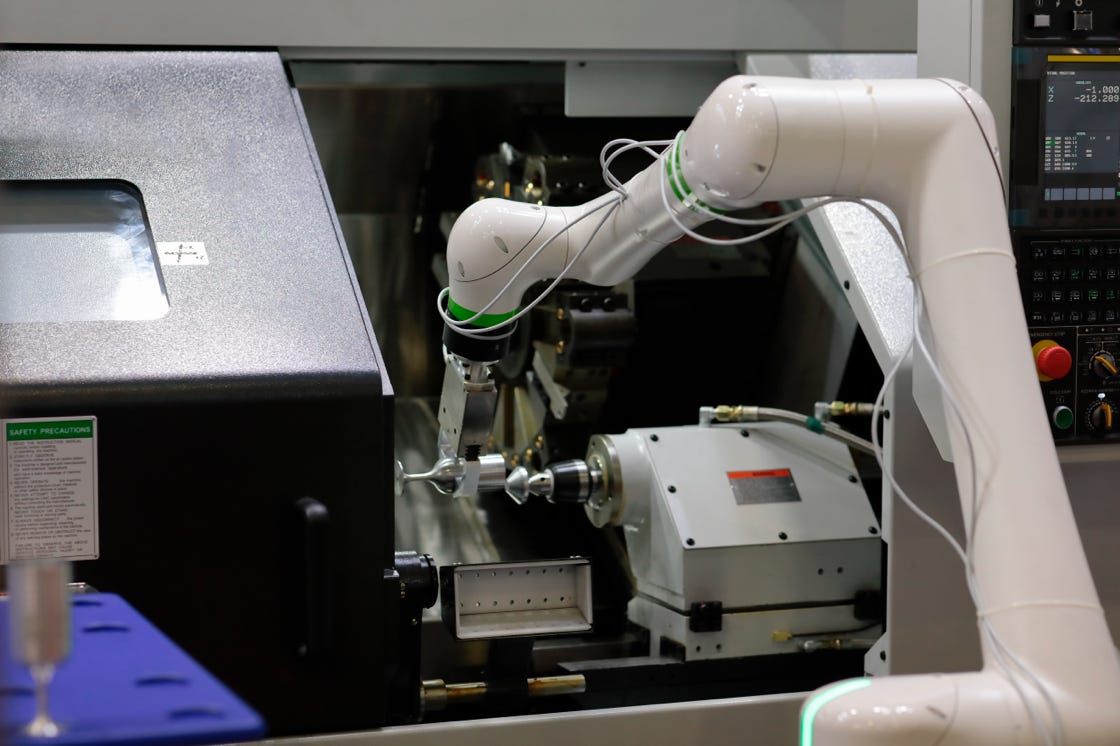

This course on Intelligent and Sustainable Machining Processes is designed to provide to the students’ knowledge on the fundamentals, technology and advances in machining. Topics include machining fundamentals, types of machine tools and their architecture, Computer Numerical Control (CNC) technology and programming (including Computer aided Manufacturing (CAM)), cutting tool technology and inspection, tool holding systems, fixtures, metalworking fluids, and advanced machining (High-Speed Machining, robotic machining, machining of difficult-to-cut materials, high precision machining and hybrid processes). Students will also have the opportunity to acquire knowledge on the most recent advances in machining technology, including on intelligent/smart and sustainable machining.

MEGR 2180-001: Manufacturing Systems

Undergraduate | Spring 2025

Instructor: Jose Outeiro

This course on Manufacturing Systems are integral frameworks that encompass the material, processes, equipment, and workforce necessary to convert raw or recycled materials into finished goods. These systems are designed to optimize production efficiency, part quality, and cost-effectiveness while addressing market demands.

This course introduces the fundamental physical principles and practices of manufacturing systems, exploring the following key topics: materials science (structure, properties, mechanical behavior, etc.), materials processing (casting, forming, welding, machining, etc.), product design and specifications (geometric dimensioning and tolerancing, etc.), quality control (dimensional metrology and non-destructive testing), and engineering economics and cost estimation.

See details here. The course is available on Canvas.

MEGR 4098/5098-002: Virtual Machining for Part Quality

Undergraduate & Graduate| Spring 2025

Instructors: Taner Tunc & Jose Outeiro

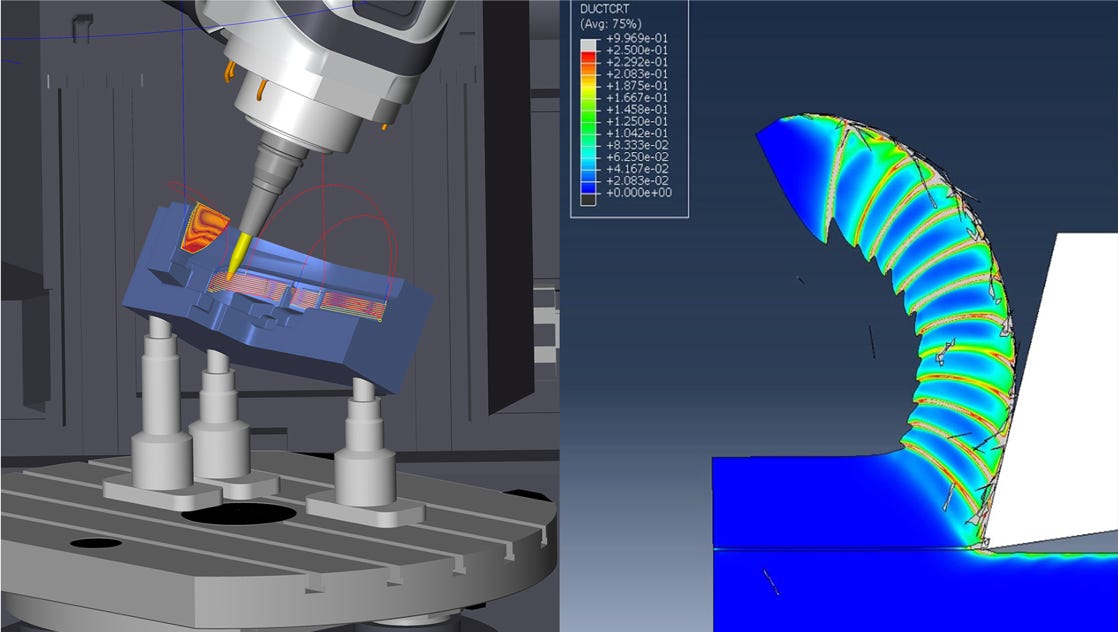

The goal of this course is to impart a detailed view of machining systems and processes. In one semester the course will cover mechanics and dynamics of machining processes such as turning and milling, analysis of machine tool dynamics through impact hammer tests and modal analysis, performing stability analysis for turning and milling processes, cutting force simulation, tool wear and surface integrity analysis. This course will be delivered in the virtual machining used for prediction and improvement of part quality context. The course will also include the relation of machining processes with computer aided manufacturing (CAM), and Computer Numerical Control (CNC). A good understanding of algebra, elementary calculus, mechanics and dynamics are required.

See details here. The course is available on Canvas.

J.C. Outeiro 2025@ all rights reserved