Austin Northcutt

-Assignments-

_______________________

Assignment 2 | Assignment 3 | Assignment 4 | Assignment 5 | Assignment 6

_______________________

Assignment 5 - Components

Problem Statement:

The wiring harness for my engine needs to

be easily removed for service in the future. It also aids in

the process of removing the motor if I ever find the need

to. This device

needs to provide a way to quickly disconnect the 60 pin

wiring harness from the cabin of the car. This particular

design uses the force from an internal spring/wavy washer in

the assembly to lock the plug to the receptacle. There are many

problems that can arise from this. If the plug is not

inserted in a specific orientation the pins and

corresponding sockets will not be lined up correctly and

could cause damage.

Assumptions:

-Two main components: The Plug and the

Receptacle

-Assembly will see vibrations from the

car and engine

-The cannon plug can only attach in one

orientation with the use of guides.

-The plug will require 1/3 of a turn to

release from the receptacle.

-Will see a slight amount of

weathering/moisture.

-Friction between the plug collar, plug,

and the receptacle during mounting.

Gantt:

Decision Matrix:

-Based

off the results of the decision matrix, I will be going more

in depth into the module that incorporates a spring loaded

collar. The criteria I chose were all weighted on how

important they were to the main concept. The ranking

scale 1-5, 5 being the excellent, shows how well the

module holds up under the given criteria.

Components:

--Main

Assembly:

--Plug Assembly:

--Receptacle:

-The

receptacle

is mounted to the firewall of the engine bay and is static.

This houses all the pins for the interior side of the wiring

harness. There

will be a single guiding groove cut into the inner diameter

to ensure the plug can only attach one way. The three

guiding cylinders on the outside diameter will be grabbed by

the collar to guide the plug into place laterally.

--Plug Core:

-The plug core is main

portion of the plug assembly.

It houses the necessary pins on the engine side of the

harness that will be mated to the receptacle. The larger circular

rib extruded on the outer diameter serves as the spring seat

as well as the collar retainer.

--Plug

Collar:

The

collar

drives the locking mechanism in the main assembly. This is mounted on

the plug core and is able to rotate freely around the core. Guiding grooves

cut at an angle on the inside diameter of the plug. These

grooves serve as guides when the collar rotates around the

receptacle’s cylinders.

As the collar rotates around the receptacle, it will

draw the core in horizontally to mate to the receptacle. No rotation is

occurring from the core, only the collar.

--Wave

Washer:

A thin wavy washer serves as the spring force to keep the two halves mated together in the final assembly. It is sandwiched between the plugs core and the collar. As the collar is rotating about the receptacle it will laterally bring the core in and compress this spring. Once the guiding cylinders on the receptacle align with the holes on the collar, the spring will force the collar back, locking the assembly together.

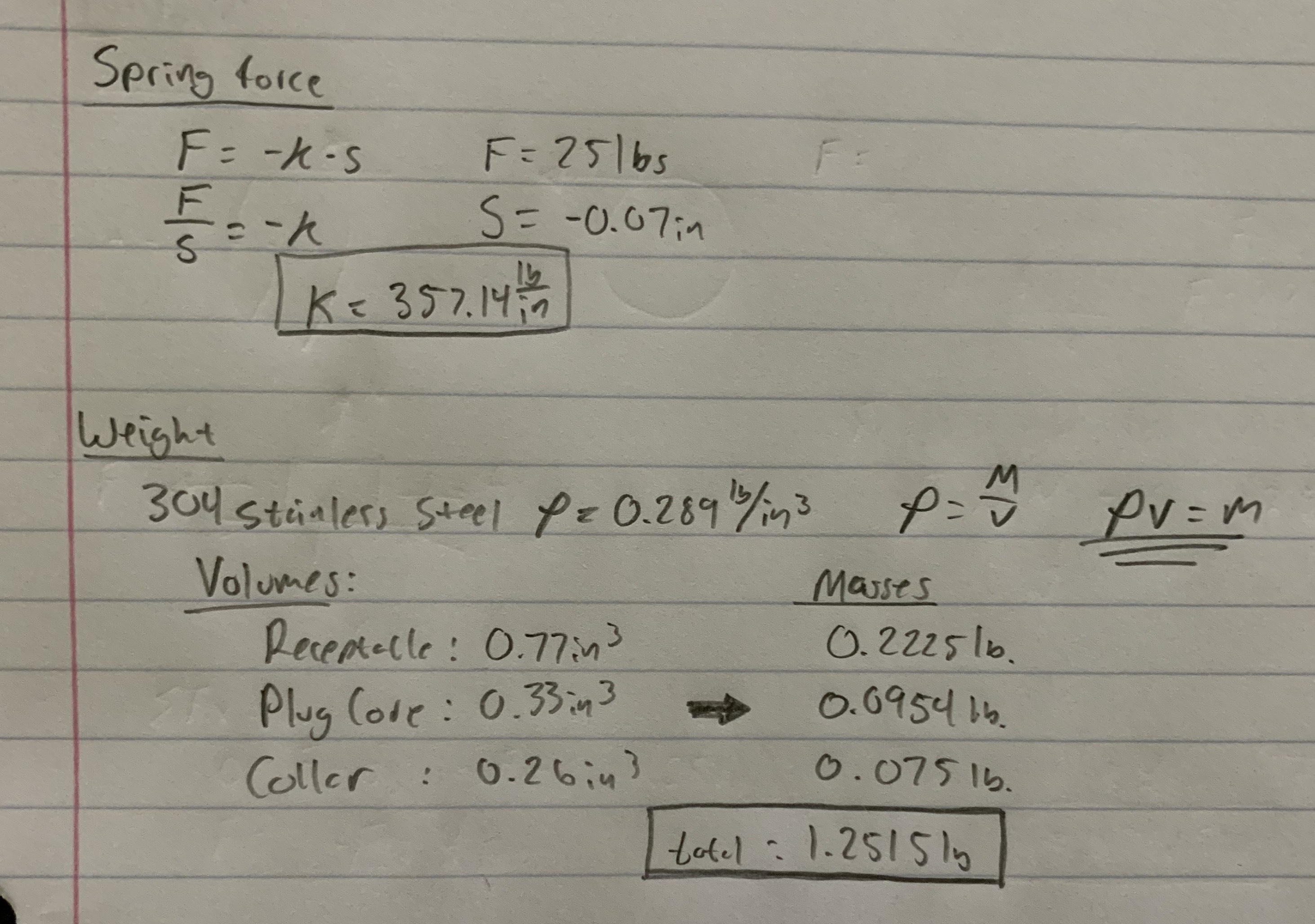

Calculations:

-There were few calculations that were needed to be derived

but the main things that required them were the wave washer

given force, mass of the objects, and the torque required to

release and tighten the mechanism.

-The Wave washer spring rate was simply

found using Hooke's law, F = -ks.

-The mass of the objects were calculated

using P = m/v.

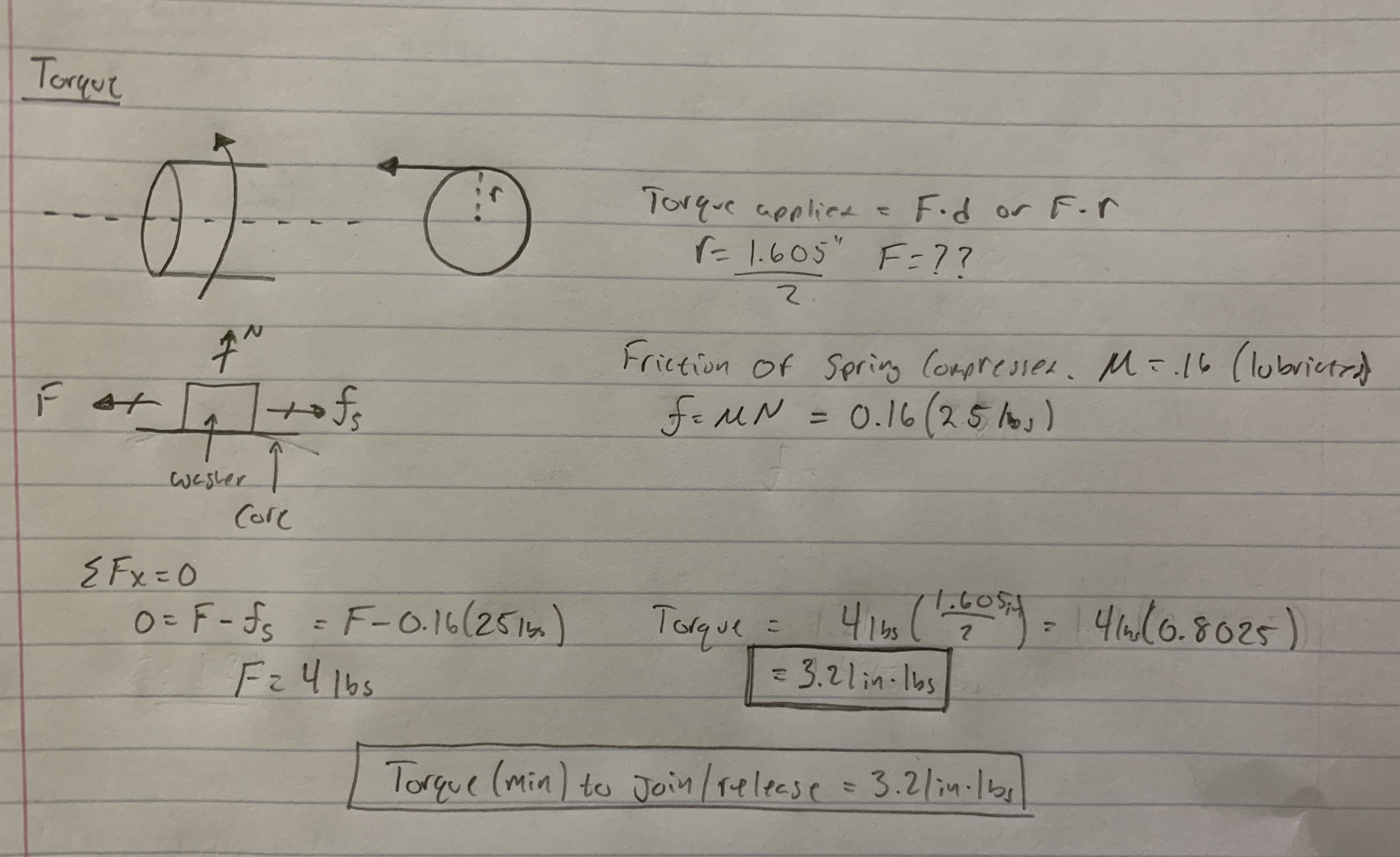

-The

torque required was found using dynamics. Friction constant of

polished steel on steel, normal force, spring force, were all

either givens or calculated.

Lessons Learned:

-How

to render in Solidworks.

-Material selection based off criteria is

now a very clear process.

-Material selection based of

elasticity/spring rate is now clear.

-How to pin motorsport connectors.

Began pinning my connector on the physical

harness.

Activity Log:

-4/9 (9am – 1:00pm) ::

Complete Decision matrix, update Gantt, and type up website

stuff in word

-4/9 (2:15 -

10pm) ::

Solidworks models and assemblies.

-4/10 (2:00 – 4:00) ::

Go in depth on formulas and decide on materials where

needed.

-4/10 (4:00 – 5:00) ::

Mock up website and make sure all images are working

-4/10 (7:00pm) ::

Submit Website

Comments:

William Hinson:

- Very organized assignment 5

flows well.

- My only complaint is there

is no final assembly. If someone who was not following

your portfolio were to look at your assignment, they wouldn't

know what it is.

James Neal:

- Great work, It was

cool seeing the motion study of the part.

- I like how in depth

you were with the material selection of 316 stainless.