Equipment

Digital Twins

Below you can find several Cyber-Physical System (CPS) used in the development of Digital Twins in manufacturing.

Intelligent Robot-Assisted Finisher System (iRAFS)

The Intelligent Robot-Assisted Finisher System (iRAFS) is a CPS consisting of an MFI RF-50 centrifugal disk finisher, a Universal Robots UR30 collaborative robot, various process monitoring equipment (including a force sensor, high-speed camera, and 3D scanner), and an AI-driven control system. iRAFS is employed in the finishing of metal Additive Manufactured parts and in the development of Digital Twins.

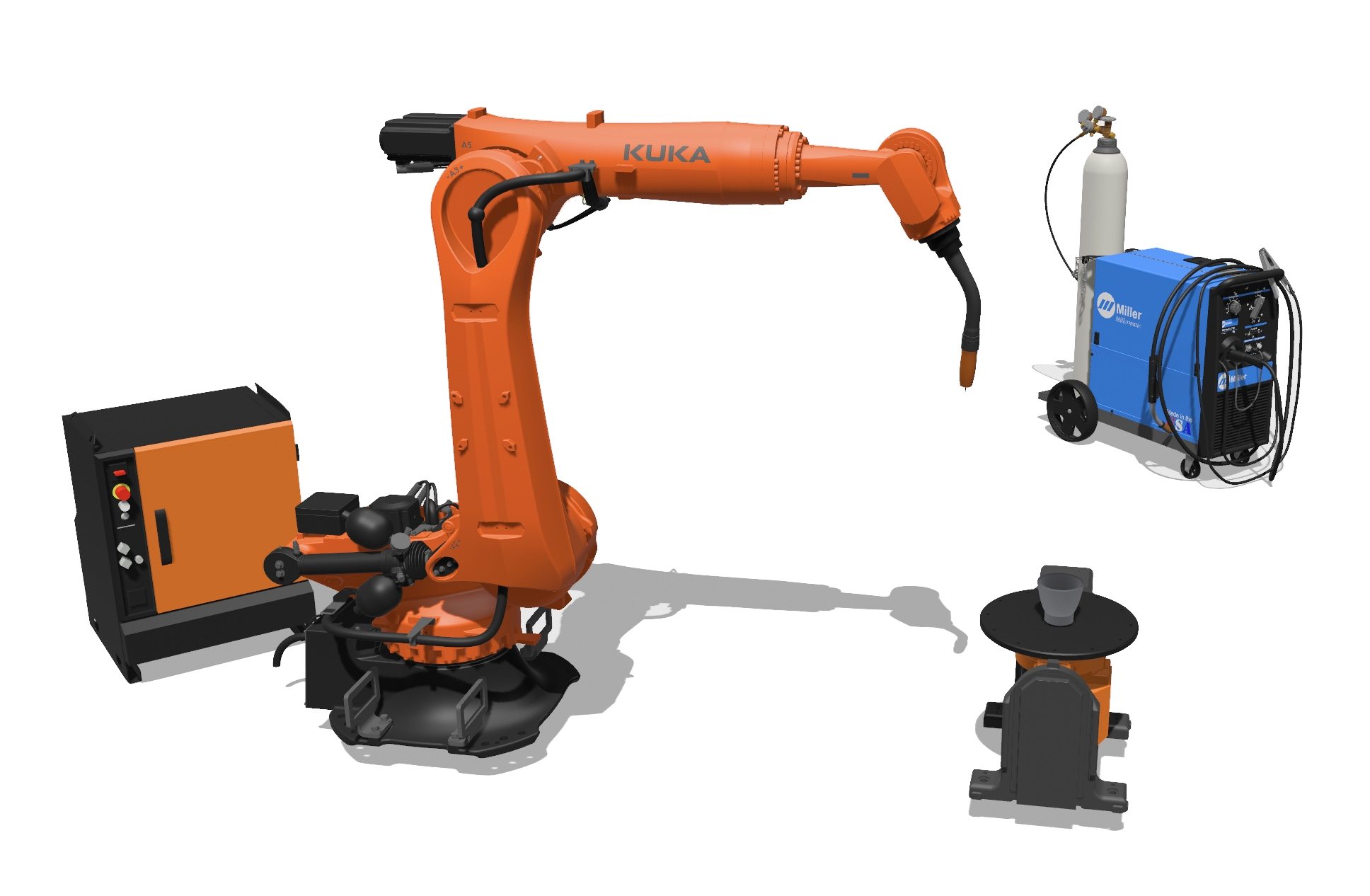

Robot-Assisted WAAM

The Robot-Assisted Wire Arc Additive Manufacturing (WAAM) system is a CPS composed by a Kuka KR 6 R700 industrial robot, a MIG welding system, a Kuka DKP-400 2-axis rotary positioner, various process monitoring equipment, and an AI-driven control system. Currently under construction, this CPS will be utilized for the development of Digital Twins in Additive Manufacturing.

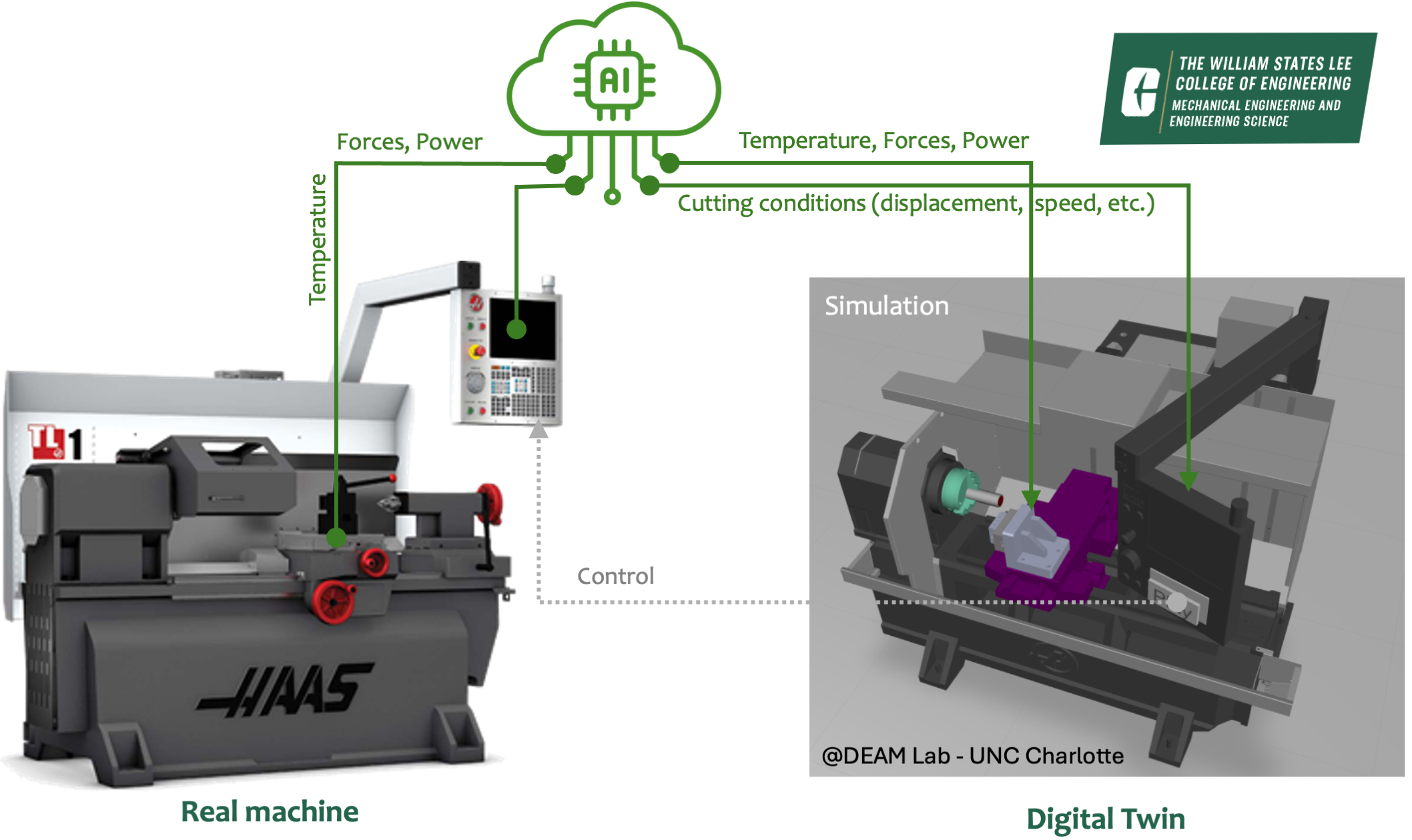

CNC Machine-Tool

This CPS, which includes a HAAS TM1 CNC turning machine, is currently under development and will be utilized for workforce training in machining processes.

Machining Simulator

The Visual Twin for ModuleWorks provides a photo-realistic simulation of machining operations on a CNC machine tool, making it an ideal tool for education and workforce development in CNC machining.