My current research focuses on algorithms for coordinating the

collision-free motions of multiple robots. By designing algorithms

that consider the complex dynamics of industrial robots, I can

coordinate the motions of robots in automotive workcells. In a related

effort, I am developing algorithms for coordinating microdroplets in

lab-on-a-chip digital microfluidics systems so they can perform

biochemical analyses. I am also developing algorithms for robotics

systems that can automatically fold objects for packaging

applications, as well for identifying protein folding pathways.

My current research focuses on algorithms for coordinating the

collision-free motions of multiple robots. By designing algorithms

that consider the complex dynamics of industrial robots, I can

coordinate the motions of robots in automotive workcells. In a related

effort, I am developing algorithms for coordinating microdroplets in

lab-on-a-chip digital microfluidics systems so they can perform

biochemical analyses. I am also developing algorithms for robotics

systems that can automatically fold objects for packaging

applications, as well for identifying protein folding pathways.

I am also interested in developing robotic systems that can automatically perform manipulation tasks. By designing efficient algorithms and planners that use the underlying task mechanics and geometry to generate solutions automatically, I have developed robots that are mechanically simple, yet very flexible. To demonstrate this approach, I have implemented robotic systems to feed and fold objects for flexible assembly and packaging. Since these systems do not require specialized effectors or sensors, they can be implemented quickly and inexpensively to shorten the time to market of new products and to reduce manufacturing costs.

Digital Microfluidic Systems

Multiple Robot Coordination

Proximity Queries

Articulated 3-D Structures

Protein Folding

Parts Feeding

When multiple robots execute tasks in a shared workspace, automatic

planners to ensure that the robots do not collide with each other

become essential. Optimized coordination of multiple robots can result

in tremendous time, energy, and cost savings. I have developed mixed

integer programming formulations to minimize task execution time and

coordinate collision-free robot motions, given individual robot

trajectories (or paths) that avoid collisions with stationary

obstacles. We have explored a progression of problems, particularly

for the case when the robots have dynamics constraints. This work is

directly relevant to the design and virtual prototyping of automotive

painting and welding workcells, and the coordination of wafer

transport robots in semiconductor fabs. This is joint work with Jufeng Peng

and Seth Hutchinson

.

When multiple robots execute tasks in a shared workspace, automatic

planners to ensure that the robots do not collide with each other

become essential. Optimized coordination of multiple robots can result

in tremendous time, energy, and cost savings. I have developed mixed

integer programming formulations to minimize task execution time and

coordinate collision-free robot motions, given individual robot

trajectories (or paths) that avoid collisions with stationary

obstacles. We have explored a progression of problems, particularly

for the case when the robots have dynamics constraints. This work is

directly relevant to the design and virtual prototyping of automotive

painting and welding workcells, and the coordination of wafer

transport robots in semiconductor fabs. This is joint work with Jufeng Peng

and Seth Hutchinson

.

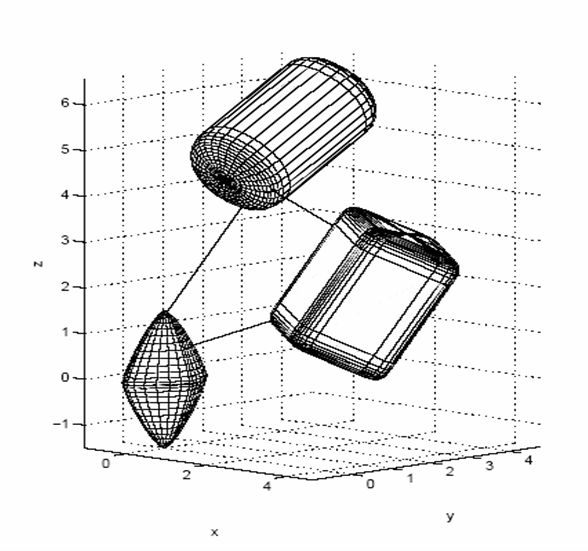

We develop an interior point approach to exact distance computation

between convex objects represented as intersections of implicit

surfaces. Exact distance computation algorithms are particularly

important for applications involving objects that make contact, such

as in multibody dynamic simulations and haptic interactions. In

contrast to geometric approaches developed for polyhedral objects, we

formulate the distance computation problem as a convex optimization

problem; this optimization formulation has been previously described

for polyhedral objects. Example implicit surfaces include planes

(polyhedra), quadrics, and generalizations of quadrics including

superquadrics and hyperquadrics, as well as intersections of these

surfaces.

We use an interior point method to solve the optimization problem and

demonstrate that for general convex objects represented as

implicit surfaces, interior point approaches are globally convergent,

and fast in practice. Further, they provide polynomial-time

guarantees for implicit surface objects when the implicit surfaces

have self-concordant barrier functions. We use a primal-dual interior

point algorithm that solves the KKT conditions obtained from the

convex programming formulation. For the case of polyhedra and

quadrics, we establish a theoretical time complexity of O(n^{1.5}),

where n is the number of constraints.

We present

implementation results for example implicit surface objects and

demonstrate that distance computation rates of about 1 kHz can be

achieved.

Joint work with Nilanjan Chakraborty, Jufeng Peng, John Mitchell .

We develop an interior point approach to exact distance computation

between convex objects represented as intersections of implicit

surfaces. Exact distance computation algorithms are particularly

important for applications involving objects that make contact, such

as in multibody dynamic simulations and haptic interactions. In

contrast to geometric approaches developed for polyhedral objects, we

formulate the distance computation problem as a convex optimization

problem; this optimization formulation has been previously described

for polyhedral objects. Example implicit surfaces include planes

(polyhedra), quadrics, and generalizations of quadrics including

superquadrics and hyperquadrics, as well as intersections of these

surfaces.

We use an interior point method to solve the optimization problem and

demonstrate that for general convex objects represented as

implicit surfaces, interior point approaches are globally convergent,

and fast in practice. Further, they provide polynomial-time

guarantees for implicit surface objects when the implicit surfaces

have self-concordant barrier functions. We use a primal-dual interior

point algorithm that solves the KKT conditions obtained from the

convex programming formulation. For the case of polyhedra and

quadrics, we establish a theoretical time complexity of O(n^{1.5}),

where n is the number of constraints.

We present

implementation results for example implicit surface objects and

demonstrate that distance computation rates of about 1 kHz can be

achieved.

Joint work with Nilanjan Chakraborty, Jufeng Peng, John Mitchell .

Manipulating articulated 3-D structures is challenging since the shape

of the object changes as it is manipulated and the number of degrees

of freedom of the object can exceed those of the manipulating robot. I

am developing techniques for the manipulation and motion planning of

"pop-up" 3-D structures. This work is motivated by the task of folding

cartons from blanks to package products such as telephones and two-way

radios, which is typically performed by human operators or with fixed

automation. Liang Lu and I developed a flexible method to fold

cardboard cartons from blanks by using interchangeable fixtures to

enable rapid product changeovers. We developed a motion planning

algorithm that generates all folding sequences for a carton by

modeling it as a robot manipulator with revolute joints and branching

links. A fixture constrains the carton motion to paths consisting of

line segments in its configuration space, and these paths are

generated by the motion planner. To illustrate the method, we

selected a folding sequence for an example carton, designed a fixture,

and demonstrated folding of the carton from blanks with an AdeptOne

robot.

Manipulating articulated 3-D structures is challenging since the shape

of the object changes as it is manipulated and the number of degrees

of freedom of the object can exceed those of the manipulating robot. I

am developing techniques for the manipulation and motion planning of

"pop-up" 3-D structures. This work is motivated by the task of folding

cartons from blanks to package products such as telephones and two-way

radios, which is typically performed by human operators or with fixed

automation. Liang Lu and I developed a flexible method to fold

cardboard cartons from blanks by using interchangeable fixtures to

enable rapid product changeovers. We developed a motion planning

algorithm that generates all folding sequences for a carton by

modeling it as a robot manipulator with revolute joints and branching

links. A fixture constrains the carton motion to paths consisting of

line segments in its configuration space, and these paths are

generated by the motion planner. To illustrate the method, we

selected a folding sequence for an example carton, designed a fixture,

and demonstrated folding of the carton from blanks with an AdeptOne

robot. Carton folding movie (YouTube)

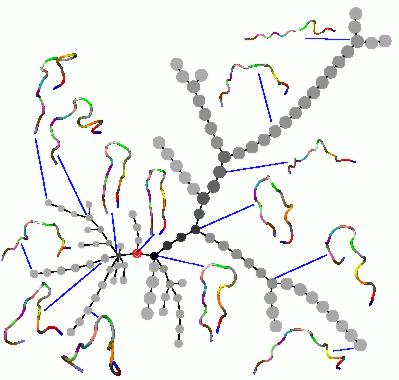

Since the 3D folded shape of a protein determines its function,

knowing the folding pathways can aid understanding of misfolding

diseases (e.g., Alzheimer's disease) and guide drug design. We are

building

on sampling-based motion planning methods, which have been recently

used

to identify feasible folding pathways for proteins with known

structure by modeling proteins as articulated robots.

Our focus is on generating

sample configurations using a hidden Markov model of protein

structures from the Protein Data Bank.

By using energy-minimized protein configurations derived from those

present in nature, we believe we can obtain biologically plausible

configurations and sample the configuration space more efficiently. We

have preliminary folding pathway results for short

proteins. Joint work with Chris Bystroff , Yogesh Girdhar, and Ted

Carlson.

Since the 3D folded shape of a protein determines its function,

knowing the folding pathways can aid understanding of misfolding

diseases (e.g., Alzheimer's disease) and guide drug design. We are

building

on sampling-based motion planning methods, which have been recently

used

to identify feasible folding pathways for proteins with known

structure by modeling proteins as articulated robots.

Our focus is on generating

sample configurations using a hidden Markov model of protein

structures from the Protein Data Bank.

By using energy-minimized protein configurations derived from those

present in nature, we believe we can obtain biologically plausible

configurations and sample the configuration space more efficiently. We

have preliminary folding pathway results for short

proteins. Joint work with Chris Bystroff , Yogesh Girdhar, and Ted

Carlson.

A parts transfer system must automatically identify actions to move

parts from initial to goal configurations. I explored the use of

graspless pushing operations, which can be used by robots to feed parts for

assembly or by mobile robots to move furniture. I proved that

any polygonal part can be moved from any known position

and orientation to any other position and orientation in the

obstacle-free plane by a sensorless sequence of pushes. I developed a

linear programming formulation and implemented a polynomial-time

planner to automatically generate sequences of pushes to perform such

parts transfer. I demonstrated these plans using a Puma 560 robot.

A parts transfer system must automatically identify actions to move

parts from initial to goal configurations. I explored the use of

graspless pushing operations, which can be used by robots to feed parts for

assembly or by mobile robots to move furniture. I proved that

any polygonal part can be moved from any known position

and orientation to any other position and orientation in the

obstacle-free plane by a sensorless sequence of pushes. I developed a

linear programming formulation and implemented a polynomial-time

planner to automatically generate sequences of pushes to perform such

parts transfer. I demonstrated these plans using a Puma 560 robot.

A fundamental question is: How many degrees of freedom does a robot

require to manipulate a part with three planar degrees of freedom? We

developed a one-joint-over-conveyor (IJOC) system that uses the

pushing motions of a single joint effector positioned over a conveyor

belt and the conveyor drift to perform parts transfer. We showed that

it is possible to manipulate all three degrees of freedom of any

polygon to move it from any known initial configuration

upstream of the effector to a specific goal configuration. I developed

a nonlinear programming formulation to automatically generate plans

for this 1JOC system and demonstrated these plans on a conveyor with

an Adept 550 robot.

A fundamental question is: How many degrees of freedom does a robot

require to manipulate a part with three planar degrees of freedom? We

developed a one-joint-over-conveyor (IJOC) system that uses the

pushing motions of a single joint effector positioned over a conveyor

belt and the conveyor drift to perform parts transfer. We showed that

it is possible to manipulate all three degrees of freedom of any

polygon to move it from any known initial configuration

upstream of the effector to a specific goal configuration. I developed

a nonlinear programming formulation to automatically generate plans

for this 1JOC system and demonstrated these plans on a conveyor with

an Adept 550 robot.

Sensorless 1JOC: We modified the 1JOC system to perform

sensorless parts transfer on a conveyor. This system can perform

a sequence of operations to bring all initially unknown positions and

orientations of the part (upstream of the effector) to the same goal

position and orientation without using sensors.

Sensorless 1JOC: We modified the 1JOC system to perform

sensorless parts transfer on a conveyor. This system can perform

a sequence of operations to bring all initially unknown positions and

orientations of the part (upstream of the effector) to the same goal

position and orientation without using sensors.

A parts orienting system must identify a sequence of actions

to bring a randomly oriented part to a goal orientation for

assembly. Since sensorless systems can orient parts (e.g. sensorless

1JOC), characterizing the advantages of using sensors is important. To

quantify the significant cycle time reduction when inexpensive sensors

that provide partial information on orientation, such as photosensors

to measure part width, are combined with actions, I proved bounds on

the lengths of sensor-based plans. I also showed that a single

sensor-based plan can orient and recognize different parts.

A parts orienting system must identify a sequence of actions

to bring a randomly oriented part to a goal orientation for

assembly. Since sensorless systems can orient parts (e.g. sensorless

1JOC), characterizing the advantages of using sensors is important. To

quantify the significant cycle time reduction when inexpensive sensors

that provide partial information on orientation, such as photosensors

to measure part width, are combined with actions, I proved bounds on

the lengths of sensor-based plans. I also showed that a single

sensor-based plan can orient and recognize different parts.

Toleranced parts: Since parts manufactured to tolerances have

to be reliably oriented, I characterized the effect of part shape

uncertainty on the orienting process. For the class of convex polygonal

parts, I defined a shape tolerance model that permits the center of

mass and the vertices to lie anywhere in disks centered at their

nominal positions. I demonstrated that the variational class of parts

defined by the tolerance model can be reliably oriented by both

sensor-based and sensorless plans despite the resulting

nondeterminism.

Toleranced parts: Since parts manufactured to tolerances have

to be reliably oriented, I characterized the effect of part shape

uncertainty on the orienting process. For the class of convex polygonal

parts, I defined a shape tolerance model that permits the center of

mass and the vertices to lie anywhere in disks centered at their

nominal positions. I demonstrated that the variational class of parts

defined by the tolerance model can be reliably oriented by both

sensor-based and sensorless plans despite the resulting

nondeterminism.

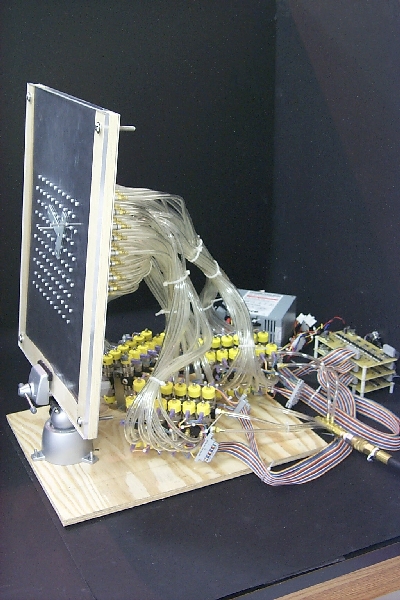

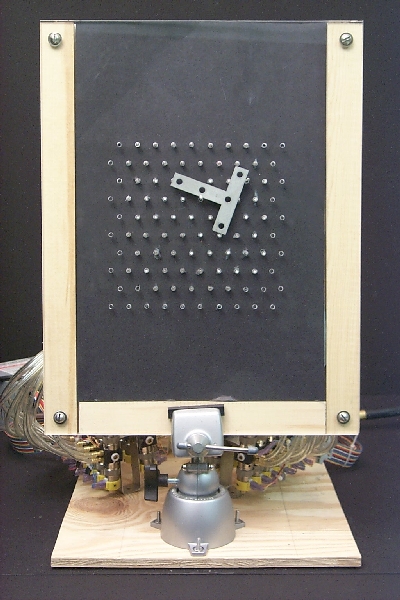

Jointly with Sebastien Blind, Chris McCullough, and Jean Ponce , I developed a reconfigurable parts orienting device that is modular and composed of simple electromechanical elements. This device, the "Pachinko machine," automatically catches and orients dropped parts of known shape using a grid of actuated pins on a vertical plate. We use a configuration space representation of the part and nest geometry to compute stable part configurations in the nests, their capture regions, and orienting plans.

Pachinko machine movie (YouTube)